|

|

Joined: Apr 2004

Posts: 3,569 Likes: 37

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,569 Likes: 37 |

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

Major Contributor

Joined: Aug 2014

Posts: 821 |

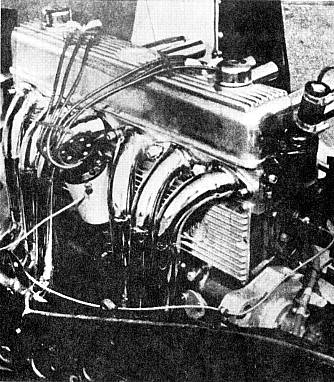

are you setting this up to take individual injectors for EFI? Looks like it with the bosses on the intake runners.

|

|

|

|

|

Joined: May 2000

Posts: 1,464

1000 Post Club

|

1000 Post Club

Joined: May 2000

Posts: 1,464 |

Injectors are best aimed at the base of the intake valves. Those boss locations may work better for vacuum taps - or nitrous injection.

FORD 300 inline six - THE BEST KEPT SECRET IN DRAG RACING!

|

|

|

|

|

Joined: Nov 2004

Posts: 420

Contributor

|

Contributor

Joined: Nov 2004

Posts: 420 |

Be nice if injector tubes were like the 360 Outlaw Sprint Cars were and reach all the way down the port to the base of the intake valve...They remove the hose and screw out the injector and pull it out of the port. It is about 10 inches long.

Last edited by SCRAPIRON, #4711; 03/23/17 04:58 PM.

Jerry Davis II#4711

ol Smokey said "one test is worth a thousand expert opinions."

|

|

|

|

|

Joined: Sep 2008

Posts: 3,674 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,674 Likes: 42 |

Just remember that the person undertaking this project is not very knowledgeable about the dynamics or mechanics of cylinder head design or airflow. And is only doing it to basically check off a box on his bucket list, and is really only a labor of love for him. So it is what it is, and has a long way to go to even be tested, much less proven. So don't expect it to be a contender by any means even against a lump port head.

Class IV CNC Machinist/Programmer

|

|

|

|

|

Joined: Apr 2004

Posts: 3,569 Likes: 37

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,569 Likes: 37 |

Just remember that the person undertaking this project is not very knowledgeable about the dynamics or mechanics of cylinder head design or airflow. And is only doing it to basically check off a box on his bucket list, and is really only a labor of love for him. So it is what it is, and has a long way to go to even be tested, much less proven. So don't expect it to be a contender by any means even against a lump port head. The head project is not mine. Not sure why you would make such a comment about someones work and passion. He may comment, but I will say he has gone to great lengths to make this a great head. It is pretty exciting that someone is trying to develop a new meat and potato product for this engine in this day and age.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Nov 2004

Posts: 420

Contributor

|

Contributor

Joined: Nov 2004

Posts: 420 |

I wish i was a expert with millions to play with.. being i am NOT "I got to dance with who brung me" I just WISH someone who WAS, would think out of the box...Be a trend setter not a trend follower. Some how make them wider,taller and get those port straighter. See i told you i wasn't a expert but a pretty good day dreamer...!!

Jerry Davis II#4711

ol Smokey said "one test is worth a thousand expert opinions."

|

|

|

|

|

Joined: Sep 2008

Posts: 3,674 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,674 Likes: 42 |

I know its not your project, Alistair contacted me originally for design consultation and input and told me that his goal was strictly to do it because he always wanted too, and had no background in how to make one really, and no real expectation it would be anything other than a "one off" or very low quantity type of product. Not knocking him at all, just informing those that questioned the bosses on the intake and that they don't align with their thinking and experience in these matters. He is just a simple guy that has a goal, but isn't an engineer or designer with those types of skill sets, and it was never his goal to make something to be on the same level with Brodix or Dart or even Sissell. I think everyone else's expectations are higher than his.

Class IV CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2007

Posts: 8

Active BB Member

|

Active BB Member

Joined: Mar 2007

Posts: 8 |

The bosses are for vacuum tapping or any bracket, NOT injection.

The same pattern is used for all three, simplicity is best.

I made my own flow bench from scratch to understand what was required,so the condescending remarks Scott about the simple guy without the skill set for this is uncalled-for, get off your high horse.

I spoke to you originally about the viability of selling a head not design consultation as you call it.

Where are the positive remarks that would have been plentiful when I joined Inliners International many years ago.

The Kiwi "can do" approach suits me best.

Alistair Parker

|

|

|

|

|

Joined: Nov 2012

Posts: 551

Major Contributor

|

Major Contributor

Joined: Nov 2012

Posts: 551 |

Josh

72 gmc lwb air ride 5 speed (soon) turbo 292 II# 6102

|

|

|

|

|

Joined: Nov 2012

Posts: 551

Major Contributor

|

Major Contributor

Joined: Nov 2012

Posts: 551 |

I think it looks slicker than snot I am also building my own intake I am not sure how well it will work but it's a lot of fun!

Now you took it to a whole nother leve . Keep it going it's looking good

Josh

72 gmc lwb air ride 5 speed (soon) turbo 292 II# 6102

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

Major Contributor

Joined: Aug 2014

Posts: 821 |

With the individual intake ports a port injection system might be something to play with down the road. I'd guess it would be easier to one-off fab one out of steel rather than cast it.

Regardless I've recently sold my inline but I like to see people trying new stuff.

...and I was really starting to hate my carb...

Good luck!

|

|

|

|

|

Joined: Sep 2008

Posts: 3,674 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,674 Likes: 42 |

Sorry if you feel my comments were condescending by referring to you as "simple", meaning average like most of us including me, they weren't meant to be. Just giving an explanation to previous comments and not meant to downplay your efforts or abilities. Its been a long time since this project got started and many are anxious to see results and a working prototype in action. Good luck, you've at least gotten a head or two cast and machined it appears. And the "can do" approach has gotten you this far so keep plugging away at it.

Class IV CNC Machinist/Programmer

|

|

|

|

|

Joined: Jul 2000

Posts: 4,592 Likes: 20

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,592 Likes: 20 |

Well this head be able to run water?

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Mar 2007

Posts: 8

Active BB Member

|

Active BB Member

Joined: Mar 2007

Posts: 8 |

Yes will run water.

Just a little background. 80% of the pattern making time is in the water jacket cores and figuring it out,what a mission. I was not comfortable with the water flow around the plugs down the intake side so I put a water gallery in that widens the head at that point.

Dissecting a typical Japanese cylinder head (masters of casting) shows very thin wall castings that take little space but a slight core shift in the common limited run, jobbing foundry means leakage before or after machining. Porosity in castings is not such an issue these days but saying that the head has extra holes in the casting for venting that get plugged.

I made the intake ports very thick for extreme metal removal !

Going cross flow on such a narrow block things get crowded if you want to keep the pushrods in the original position.

Many aftermarket aluminium V8 heads have surprisingly little water jacketing on the intake side I discovered.

Alistair

|

|

|

|

|

Joined: Jul 2000

Posts: 4,592 Likes: 20

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,592 Likes: 20 |

Nice Job on it so far anyway. Have you had a chance to run any flow #s On it yet? And What size valves will it be able to handle?

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Mar 2007

Posts: 8

Active BB Member

|

Active BB Member

Joined: Mar 2007

Posts: 8 |

When I flowed the plastic pattern, 180 cfm on the exhaust and 270 on the intake with 1.6 and 1.94 valves, 2.02 fits no problem. The difficulty was getting a good seat in the pattern. I haven't flowed a cast head yet as the first two were cut up to check all over the casting for consistent thickness. I moved the valves so the big pushrods do not touch the side of the block but they are still at the original centers.

|

|

|

|

|

Joined: Oct 2009

Posts: 471 Likes: 9

Contributor

|

Contributor

Joined: Oct 2009

Posts: 471 Likes: 9 |

|

|

|

|

|

Joined: Apr 2003

Posts: 1,542 Likes: 16

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,542 Likes: 16 |

The Kiwi "can do" approach suits me best.

I am a big fan of doers . . . and triple Webers! Not to mention the perseverance to stick with one's vision even when the realization takes time. To cut up your prototypes in order to tick and tie the details on the casting internals is proof enough for this inliner that you are serious about getting this right. Are you really going to try to fit a dizzy to the hot side of the engine? Some of the earlier photos suggested so. Coil over plug with a crank trigger might prove easier - though hardly vintage . . . What car is this power plant destined for?

|

|

|

|

|

Joined: Mar 2007

Posts: 8

Active BB Member

|

Active BB Member

Joined: Mar 2007

Posts: 8 |

Thanks for the interest guys.I figure there is an insulation out there in this high tech space age thin enough to shroud and protect the distributor on the 250, the 292 is easier.The right angle drive idea is great on a truck but a Nova not good.

I do not think it necessary to go the crank trigger way at this stage.

When running on the test stand I will put a thermocouple on it to see what's happening.

This head with early valve cover and traditional carbs etc will look old school as per the Wayne head.

I had to slightly bulge the end of the metal valve cover to fit over the rockers, hardly noticeable, Tom will have it sorted with his cover.

Alistair

|

|

|

|

|

Joined: Apr 2003

Posts: 1,542 Likes: 16

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,542 Likes: 16 |

Ah yes that Wayne Horning look  now I am even a bigger fan of the build. With the dizzy hole so far forward I guess the header tubes can just sweep back . . . Will the outer perimeter of the head eventually be trimmed/slimmed once the internals are sorted?

|

|

|

|

|

Joined: Oct 2009

Posts: 471 Likes: 9

Contributor

|

Contributor

Joined: Oct 2009

Posts: 471 Likes: 9 |

|

|

|

|

|

Joined: Dec 2017

Posts: 17

Active BB Member

|

Active BB Member

Joined: Dec 2017

Posts: 17 |

|

|

|

|

|

Joined: Jan 2010

Posts: 349

Contributor

|

Contributor

Joined: Jan 2010

Posts: 349 |

Any update on this glorious project?

I am often heard saying “bit of kiwi ingenuity” having lived there!

|

|

|

|

|

Joined: Sep 2017

Posts: 209 Likes: 2

Contributor

|

Contributor

Joined: Sep 2017

Posts: 209 Likes: 2 |

Any chance they will be making a blower manifold?

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

I would guess that they didn't anticipate enough sales volume to warrant the R&D.

|

|

|

|

|

Joined: Sep 2017

Posts: 209 Likes: 2

Contributor

|

Contributor

Joined: Sep 2017

Posts: 209 Likes: 2 |

I don't have a distributor. I will need an intake for a 4-71 blower, any takers? Will stainless header flanges be available?

Last edited by mick53; 12/10/18 03:14 AM.

|

|

|

|

|

Joined: Sep 2017

Posts: 209 Likes: 2

Contributor

|

Contributor

Joined: Sep 2017

Posts: 209 Likes: 2 |

It would be nice to find someone that is building a stout 292 with a billet crank and maybe say 3 Roch, 2 bbl carbs. Crank fired ignition, external oil pump and a 4-71 blower. That would be a great test for it. I would put that guy at the top of my waiting list. Especially if it were being built by someone like Gaerte Racing Engines. Tom might know such a guy. It would be all the rage at SEMA in say a 53 1/2 ton with TKO 600 and Frankland quick change rear end. Just a thought.

|

|

|

|

|

Joined: Jan 2013

Posts: 80

Active BB Member

|

Active BB Member

Joined: Jan 2013

Posts: 80 |

Any updates from Mr. Alistair?

|

|

|

|

0 members (),

48

guests, and

38

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|