|

|

Joined: May 2000

Posts: 1,464

1000 Post Club

|

1000 Post Club

Joined: May 2000

Posts: 1,464 |

Our 240 Ford with a Holley works best (no stumble) with #37 shooters.

Ported signal vacuum works better as far as eliminating stumble than straight manifold vacuum.

If your carb does not have a ported connection you can "band aid" the problem by installing a Ford Spark Delay Valve (SDV)in the vacuum line. These come in various restrictor sizes and are color coded by bleed-off time.

FORD 300 inline six - THE BEST KEPT SECRET IN DRAG RACING!

|

|

|

|

|

Joined: Feb 2014

Posts: 505

Major Contributor

|

Major Contributor

Joined: Feb 2014

Posts: 505 |

Is that maybe the purpose that this valve in the vacuum line to my distributor advance serves?  It's hooked to a thermal sensor valve that is separate from the one that controls the vacuum for the EGR and EVAP, which is only opened when warmed up. So the one on top for the timing advance may be only allowing vacuum when engine is cooler? But the round plastic piece, attached to the water neck valve, may be a check valve as well to prevent sudden vacuum lose and bog?

|

|

|

|

|

Joined: May 2016

Posts: 468 Likes: 4

Contributor

|

Contributor

Joined: May 2016

Posts: 468 Likes: 4 |

YEAH!! My 390 ha no provision for ported vacuum. I plan to put a check valve in line this spring to help maintain full vacuum to the advance. My advance is set up to add timing as soon as the engine starts and idles. I can kill vacuum and raise the timing and three's no bog, but it makes it hard to start when the engine temp is on the hot side.

The engine in question is an old 153 cid. 4 cylinder out of a '67 Nova.

Never use a minor caliber bullet on a major caliber adversary

|

|

|

|

|

Joined: Feb 2014

Posts: 505

Major Contributor

|

Major Contributor

Joined: Feb 2014

Posts: 505 |

YEAH!! My 390 ha no provision for ported vacuum. I plan to put a check valve in line this spring to help maintain full vacuum to the advance. My advance is set up to add timing as soon as the engine starts and idles. I can kill vacuum and raise the timing and three's no bog, but it makes it hard to start when the engine temp is on the hot side.

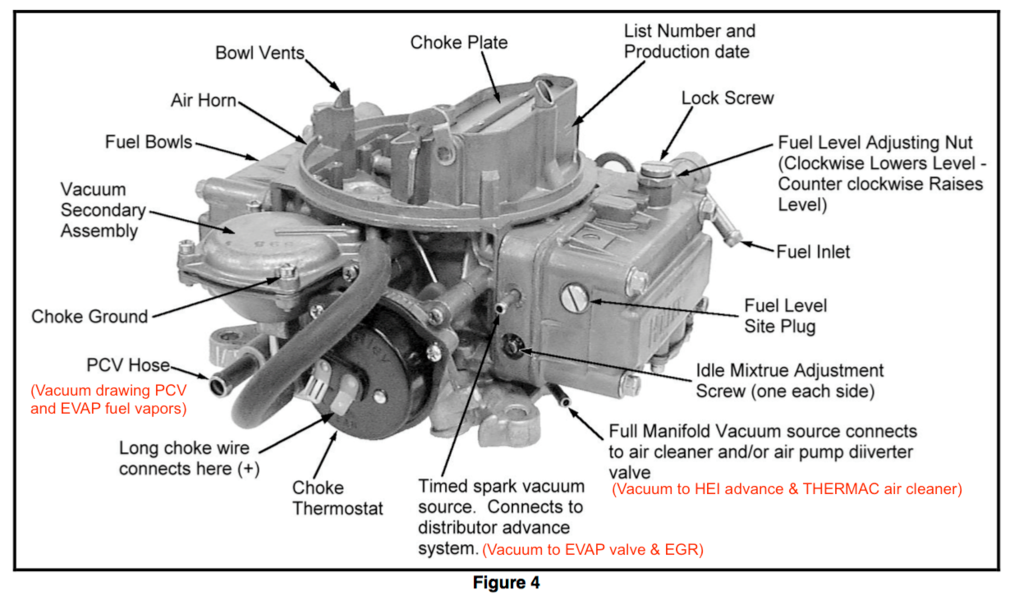

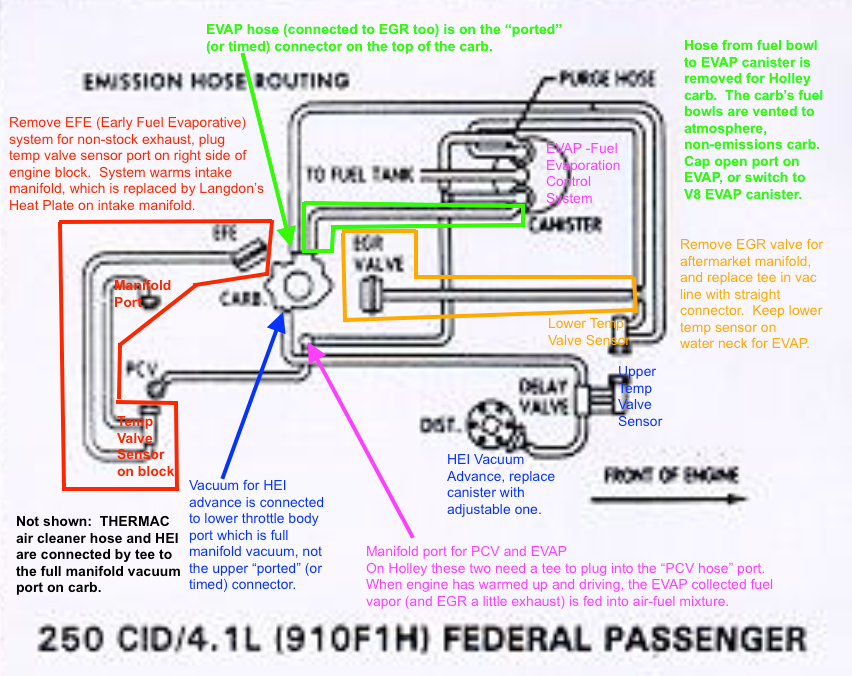

The engine in question is an old 153 cid. 4 cylinder out of a '67 Nova. This is what I worked out for switching my Monojet on my Chevy 250cid with the Holley 390cfm:

|

|

|

|

|

Joined: May 2016

Posts: 468 Likes: 4

Contributor

|

Contributor

Joined: May 2016

Posts: 468 Likes: 4 |

My 390 is one of the NASCAR racing carbs. It doesn't have ANY vacuum ports. It is a double pumper with jet plates and no power valves. The PCV is tapped into the intake manifold plenum. I have a tee in line to supply vacuum to the advance servo. I fabricated a reservoir for the vac. advance and I'm adding the check valve as I said.

I am not really all that displeased with how it is working now, BUT!! if I am not more satisfied after adding the check valve, I will drill a vacuum circuit for ported vacuum later this summer.

Last edited by Blackwater; 03/03/17 05:00 PM.

Never use a minor caliber bullet on a major caliber adversary

|

|

|

|

|

Joined: Nov 2013

Posts: 482

Contributor

|

Contributor

Joined: Nov 2013

Posts: 482 |

The valve in the picture is the "cold trapped spark advance". What the system does is "trap" the vacuum to the vacuum advance unit when the engine is cold so that the timing doesn't retard when the engine is cold and you step on the gas pedal.its supposed to help with a cold engine stumble problem. Once a certin coolant temp is reached the switch opens, causing the vacuum advance unit to work normally. Jay

|

|

|

|

|

Joined: Nov 2016

Posts: 6

Active BB Member

|

Active BB Member

Joined: Nov 2016

Posts: 6 |

You might consider putting on a 50cc pump from a larger Holley. That would feed more fuel than the 30cc stock size. I've done it before when I had bogging problems. It wasn't a magic bullet but it did help. I think it would you to go back on the shooter size and get more duration out of the incoming shot. I didn't do that, I drilled my shooters out, which is not recomended. But between that and the power valve being swapped later the bog problem went away. My problem was with a cold engine. Once warm I didn't have the issue, but NH is coler than CA.

Good Luck, you are getting there.

David Chandler

|

|

|

|

|

Joined: Apr 2006

Posts: 534

Major Contributor

|

Major Contributor

Joined: Apr 2006

Posts: 534 |

Blackwater,

Do you know what jets you're running in that 390 Holley since it has no power valves for extra fuel? Is it rich enough to give full power and still lean enough to cruise?

|

|

|

|

|

Joined: May 2016

Posts: 468 Likes: 4

Contributor

|

Contributor

Joined: May 2016

Posts: 468 Likes: 4 |

My buddy, Jimmy Bridges from down in Nashville built it and I have the jet sizes written down, but I don't recall them. He sent me four more sets in two step increments up, but I haven't gotten back to the project yet this spring. I do know that it is set up square, that is the same jets on all four corners.

It is probably a little lean on top end, because if I run it over 80 mph it starts to run a little hot in the summer heat, but if I back down to 70 it runs fine.

If you eliminate the power valves, you should step the jets up at least four, and as many as eight steps to start with. I don't like running power valves because they tend to rupture if the engine backfires and can flood and wash down an engine.

Mine is set up on a sheet metal and tubing tunnel ram intake and is mounted sideways with the bowls to the left and right! I'm in the process of collecting up the parts to bore and stroke my little engine out to 175 cid. Bridges has already built a big port head with major porting, larger valves and a hump kit, as well as new valve springs and keepers and retainers and 7/16" rocker studs.

I'm a long way from finished with the tuning and it still has a stumble if you slam the pedal to the floor from anything less than midrange RPM. I am going to put the big accelerator pumps back on.

Never use a minor caliber bullet on a major caliber adversary

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

Major Contributor

Joined: Aug 2014

Posts: 821 |

Power valves no longer blow out on modern carbs. I've backfired more than a few messing with things and haven't blown one yet.

|

|

|

|

|

Joined: May 2016

Posts: 468 Likes: 4

Contributor

|

Contributor

Joined: May 2016

Posts: 468 Likes: 4 |

I blew one on this carb!! It is why I had someone else rebuild it! Of course, the NASCAR 390 is a lot different from most of the other 390 Holleys.

It looks more like the old 850 double pumper. It is all mechanical. No vacuum secondary. no choke. Not even a choke horn. No vacuum ports of any kind.

If you're dealing with one of those with the vacuum secondary, you can change the spring in the secondary servo/dashpot to open faster or slower to tune the stumble or bog, or to bring the secondary in faster. I've also seen the vacuum passage drilled or bushed to increase or decrease the vacuum signal.

Last edited by Blackwater; 03/06/17 06:58 PM.

Never use a minor caliber bullet on a major caliber adversary

|

|

|

|

|

Joined: May 2003

Posts: 218

Contributor

|

OP

Contributor

Joined: May 2003

Posts: 218 |

More RADAR comments to your recent replies.

Tlow #1716: I may add heat. My unheated triple 2 barrel Webber setup does not stumble, but the Holley does hot or cold. The 3 Webbers work fine but the Holley seems to pull much better once the stumble passes.

Blackwater: I'll try adding a small vacuum can in the secondary vac. line. It could be the Holley 8007 has a spot where ported vac. drops off and messes up the spark advance.

Also changing from a 0.025 to a 0.028 squirter and going back to an 8.5 Power Valve.

Thanks again for all the comments.

FranK Hainey

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

Major Contributor

Joined: Aug 2014

Posts: 821 |

I'm running a 47 squirter...

|

|

|

|

|

Joined: Jan 2010

Posts: 493

Contributor

|

Contributor

Joined: Jan 2010

Posts: 493 |

Inches is inches, be they inline or side by side.

for a 250 (close to a 265 V-8) or a 302 (close to a 283,289,292,307,312, etc.) All are good starting points to adapt to our sixes. Use the latest (Up to and including 1967) for best power valving and smoothest operation....1968 and later begin have many concessions to smog control...making adaptation to the sixes more difficult in the ways of drivability especially for the automatic cars where you don't have the ability to "feather' the clutch to prevent a stall or a stumble. With Doug Roe's Rochester book in hand the Q-jet is everything you could need in the way of a single carb. That book will tell you how to modify every circuit in it, both smog and presmog models. 750 cfm should be plenty for any six. This carb was used on 500 inch Caddys...down to the 230 inch Pontiac OHC--Doug Roe ran one on the four cylinder Baja mini Boots. We have a member in the North Texas Chapter running a Q-jet on a pinto four cylinder 1600 (100cubes)maybe I'm lying-it may be a 2.0 liter. The secret is the tiny primary barrels--the 2.25 back barrels only come in as needed by the adjustable air valve--every thing adjustable on the Holleys is also adjustable on the Q-jet with Roe's book. I've seen Q-jets at the swap meets for as little as five bucks--you can't beat that, the same primary size of a 390 Holley with a bonus of 360 more air flow controlled cfm. This would be my choice for size, flexibility, and price.....just sayin'

|

|

|

|

|

Joined: Jan 2010

Posts: 493

Contributor

|

Contributor

Joined: Jan 2010

Posts: 493 |

yep, theirs was 950 CFM, with the back "barrel" being a 1-3/4" wide "slot" with the same old front barrels of the 850. Yours is a clever simple idea. And if done on a vacuum secondary carb, is a real good idea...lots of easy to get Holley tuning parts available...but I still like Q-jets

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

Preacher, what has happened for so long is that too many inline tinkerer's have simply chosen the wrong carbs for the task. Over time, this has skewed manufacturers perception as to what carbs are truly in demand. This unfortunately has driven down the costs of the "wrong" carbs, while the "correct" ones are still pricey, but still the better choice. Holley has invested hundreds of thousands of dollars in Research and Development to provide carbs to fit and suit every need including performance, economy and both combinations together, but the "bigger is better" mentality is ingrained so deeply it still makes many choose the "wrong" carb even though voices of experience tell them otherwise. Over the last 40 years, if all the inline guys had purchased the "correct" carb to start with, this supply and demand for manufacturing would have brought the price of them down to where the price of the "wrong" carbs are priced today. Most of the original aftermarket 4 BBL inline engine intakes were meant to use the WCFB carbs because they were closely sized to the needs of these engines, then and now, that's why they are drilled for that bolt pattern. So trying to re-invent a solution that Holley and other manufacturers have already done is really futile.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Nov 2013

Posts: 482

Contributor

|

Contributor

Joined: Nov 2013

Posts: 482 |

I'm poor so I only have half of a Q-jet. Jay

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

The Rochester 2GC are an excellent choice and better suited cfm-wise than most other choices.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Nov 2013

Posts: 482

Contributor

|

Contributor

Joined: Nov 2013

Posts: 482 |

I totally agree about the 2gc. With a little machine work either, but especially the small base could be made to fit a stock 1bbl manifold without an adapter. Or if that nice 2bbl intake that you drew up is ready. Is it in production? Either of the two small base sizes (one of which I have never seen) or the 352 or 381 cfm large base would work well with a stock or near stock engine. There is even a large base 2gc that has 1 7/16 throttle bores and 1 3/32 Venturi like the small base. I didn't know that such a carb existed til I found out I had one in my garage! I went with a Dueljet instead. Took a special adapter but I am very happy with the result on a stock engine except no cat converter and a glass pack. Very good throttle response. Jay

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

Jay, I just got my third intake manifold design cast from 2016, so that is going to be the next one. Should have done it first! LOL

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Nov 2013

Posts: 482

Contributor

|

Contributor

Joined: Nov 2013

Posts: 482 |

Ok I'll bite. What intakes for what engines are ready? Slant 6? I just wish I knew more about Holley carbs to help out the OP. It seems like the 302 doesn't breathe very well when compared to a simular size SBC even when the SBC has low performance heads. If I had his engine I'd go with a Q Jet or a 400 CFM carter, mostly because I have more experience with these two carbs. Jay

|

|

|

|

|

Joined: Feb 2014

Posts: 505

Major Contributor

|

Major Contributor

Joined: Feb 2014

Posts: 505 |

Jay and I have been discussing the Rochester 2GC options using an adapter on the Monojet intakes. What we've found to be available:

Base (bores) - Venturi - CFM 2bbl (4bbl equivalent)

1.25" (1-7/16") - 1-3/32" - 278cfm (197cfm)

1.25" (1-7/16") - 1-7/32" - 311cfm (220cfm)

1.5" (1-11/16") - 1-3/32" - 278cfm (197cfm)

1.5" (1-11/16") - 1-3/16" - 352cfm (249cfm)

1.5" (1-11/16") - 1-1/4" - 381cfm (269cfm)

1.5" (1-11/16") - 1-5/16" - 423cfm (299cfm)

1.5" (1-11/16") - 1-3/8" 435cfm (308cfm)

The largest one, used on big blocks, seems to be available for around $94 as new part quite readily on eBay. But the 381cfm one, used on the L65 Chevy 350, is much harder to find as a new carb.

The 278cfm seemed to be available with either a top that fit the 2-5/8" air cleaner base, or the 3" air cleaner base of the other large base 2GCs.

Last edited by Lifeguard; 03/15/17 05:27 AM.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Oct 2009

Posts: 471 Likes: 9

Contributor

|

Contributor

Joined: Oct 2009

Posts: 471 Likes: 9 |

What is next on your hit list for casting? Intake manifolds, valve covers, side plates, thermostats housings?

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

What is next on your hit list for casting? Intake manifolds, valve covers, side plates, thermostats housings? Many more of all of the above! I designed, made the patterns and had cast all 3 of these intakes in just 6 short months in 2016 beginning only in March. Plus having so many other distractions in the way of completing several other designs. 2017 should be very bountiful because I have cleared my plate of these other distractions now.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

Here is the new milling machine I just bought. Its a beast at over 10,000 lbs. It will take care of all the heavy duty milling operations I have in store for these parts on the drawing board. I also have gotten into a lot of heavy fabrication chores for the LS racing crowd along with some intense block modifications these guys are doing, so i'm no longer challenged with having the inability to do certain tasks now.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

Nice looking parts. The Mill looks nice. Seen one of those in person. Massive. You might need 2 more arms to run it.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

Thanks, I couldn't pass up the deal, it has 60" of table travel in the X axis and power feed in all 4 positions as well as rapid traverse. Working on getting it moved right now. It is Massive that's for sure.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Aug 2003

Posts: 353

Contributor

|

Contributor

Joined: Aug 2003

Posts: 353 |

Nice looking milling machine.

Does that run on 3 phase 220?

pete

Pete

64 Chevelle

61 C30 Panel truck

|

|

|

|

|

Joined: Aug 2003

Posts: 353

Contributor

|

Contributor

Joined: Aug 2003

Posts: 353 |

I totally agree about the 2gc. With a little machine work either, but especially the small base could be made to fit a stock 1bbl manifold without an adapter. Jay Jay, You know there's a lot of empty space in the intake that is the exhaust passageway. There's more to it than just drilling 2 new holes. (Did it for a Holley/Weber 2 bbl on my 194) For small carbs I'd suggest using an Offy intake with a custom drilled carb plate to replace the stock 4 barrel plate. Pete

Last edited by Chevelle292Wagon; 03/18/17 05:35 PM.

Pete

64 Chevelle

61 C30 Panel truck

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

Nice looking milling machine.

Does that run on 3 phase 220?

pete Thanks! Yes, its 3 phase 220V, so i'll need to get another phase converter to run it.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: May 2003

Posts: 218

Contributor

|

OP

Contributor

Joined: May 2003

Posts: 218 |

It's Radar again playing with the 390 cfm Holley . I tried a 0.028 accel. pump nozzle and added a small vacuum chamber in spark advance line. The vacuum chamber made the engine diesel when turned off. The stumble is still present. Taking off the Vacuum Chamber now.

The earlier changes made to the Power Valve and the larger nozzles has made he stumble less. The stumble occurs just after the car is rolling and the accelerator is pressed down quickly to gain speed. Taking off in traffic is a problem. If I really rev up the engine before the clutch is engaged it takes off fine.

Just ordered 0.032 and 0.035 nozzles. Hope they work- I'll let you know.

FranK Hainey

|

|

|

|

|

Joined: Nov 2013

Posts: 482

Contributor

|

Contributor

Joined: Nov 2013

Posts: 482 |

Radar, it seems like going richer with power valve (sooner as vacuum drops off) and bigger squriters for the pump is making it better. Chevelle 292 Wagon, isn't there some kind of metal sleeve inside the stock intake that directs fuel flow? IIRC someone here opened up the stock intake to the Holley/autolite 2100 bolt pattern. He had to epoxy on the inside of the intake I believe. On my 1bbl intergrated head the bottom of the intake IS the exhaust manifold! On a 2bbl intergrated head, there is a metal exhaust gasket that forms the bottom of the intake. Jay

|

|

|

|

|

Joined: May 2003

Posts: 218

Contributor

|

OP

Contributor

Joined: May 2003

Posts: 218 |

This is a delayed follow up to my earlier posts above.

Here is what I have learned about tuning the stumble out of a Holley 4 barrel. The fix depends on when the stumble takes place relative to initial takeoff.

Immediate Stumbles are fixed by increasing the squirter size with placing cam screw in hole 1.

Delayed Stumbles ( 1 or so seconds after takeoff) are fixed by decreasing the squirter size and moving the cam screw to position 2.

I had a delayed stumble in my Holley 8007, 390 cfm carb. on a mild GMC 302. It was caused by emptying the accelerator pump chamber too fast. Going to a smaller squirter extends the stream of raw gas longer. Switching to Cam screw hole 2 delays the cam action slightly, which also extends the stream. The extended stream eliminated the delayed stumble problem.

FranK Hainey

|

|

|

|

|

Joined: May 2000

Posts: 1,464

1000 Post Club

|

1000 Post Club

Joined: May 2000

Posts: 1,464 |

.037" - .040" squirters cured my 390 woes. It may be killing ants with a sledge hammer but it worked. Shame on Holley for letting this problem continue on the 390 for years.

FORD 300 inline six - THE BEST KEPT SECRET IN DRAG RACING!

|

|

|

|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

Active BB Member

Joined: Aug 2013

Posts: 78 |

what a great thread, excellent read. radar, how is your carb tuning going?

Side question, what are your thoughts on running a Weber 2 barrel carb like the 38/38DGES Clifford sells?

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

AFAIK that's synchronous (both barrels open together), either 360 or 390 CFM @ 3.0 Hg" (if rated as a 2-bbl.) depending on the venturi size (27mm or 30mm).

|

|

|

|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

Active BB Member

Joined: Aug 2013

Posts: 78 |

AFAIK that's synchronous (both barrels open together), either 360 or 390 CFM @ 3.0 Hg" (if rated as a 2-bbl.) depending on the venturi size (27mm or 30mm). I'll have to measure my venturi's one day to get the exact size but I did read the carb is synchronous. Seems to be mixed feelings about running/fine tuning the Weber carbs. Come to think of it, my internet research shows that's how people tend to feel about all carbs while everyone's favorites are different. Many years ago I had a 327sbc bored 20 over w/a Chet Herbert cam, camel back heads, headers bla bla bla....ran incredible on a rebuilt Quadrajet, only ok when I swapped it for a Carter. Although I had a Carter tuning kit and was able to swap the needles in the parking lot at will and that was pretty cool, never did run as strong as the Quadrajet.

Last edited by moregrip; 01/14/19 12:43 AM.

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

The 38/38's 27mm venturis are the same size as the 1-1/16" primary venturis on the known-to-work list #8007 Holley 390 CFM 4-bbl, which means the off idle and response should be good.

|

|

|

|

|

Joined: May 2016

Posts: 468 Likes: 4

Contributor

|

Contributor

Joined: May 2016

Posts: 468 Likes: 4 |

In the hands of the right tuner, the pre-electronic QuadraJet carburetor is one of the best street carburetors extant!! It isn't simple, but it is so tunable that GM made it work for engines from 230 cubic inches to 455 cubic inches with the same basic configuration. This isn't including the larger unit made for the 500 cubic inch Cadillac, (which,by the way, can be made to work on even larger displacement engines)!!

Tuned properly, it works better, (all around) than any other non-electronic carburetor ever made for the street. Once you get it sorted out, you close the hood and forget about it!!

Granted! Tuning isn't "so simple a caveman can do it", but it ain't "rocket surgery" either!! John Lingenfelter wrote SVERAL articles on it and explained it step by step in vivid detail!!

For smooth, everyday use and performance, I STILL like a Qjet for non fuel injected projects.

Never use a minor caliber bullet on a major caliber adversary

|

|

|

|

0 members (),

57

guests, and

339

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|