|

|

Joined: May 2014

Posts: 25

Active BB Member

|

Active BB Member

Joined: May 2014

Posts: 25 |

That was my old setup. PM me if you have any questions. Glad to see it's going to someone will use it for it's intended purpose.....BOOST!

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

Welcome Sdver! Thanks for the kind words. I'll be checking up on you too. So I just re-read this page now that I have the means to get whatever parts list I come up with. What I'm thinking is stock pushrods and rockers assuming I keep under .550" lift (got that from santucci's book). Then just buy a new set of stock lifters. Call Lunati or Comp and have them make me cam for my application and buy the recommended springs for that new cam. Get 1.94"/1.6" valves and lump ports. Take the new valves and lump ports to a machine shop and have them do the valve job (forgot to mention buy new valve guides, seals, retainers, and keepers (or is that necessary)) with the new valvetrain parts, put in new cam bearings, and then put the lump ports in. Are there any other engines that use the same valves as the 250? I found the 1.94"/1.6" combo for small block chevys that looks like it'd fit http://www.ebay.com/itm/Chevy-16-305-400...ef4b327&vxp=mtrWhat parts are dependent on what? Like are keepers dependent on the valves or the springs or both? Do springs need to be matched with the cam cards? Are retainers matched with springs or valves? Should I need any more than .550" lift? Isn't that only .1" over stock? Or is it the duration and overlap that make the big difference on turbo cars? P.S. - Got my dad's GS 400 running like a champ this weekend. Full new rear suspension including rear sway bar. Turned out he had a cracked starter which was why it was so hard to start all the time and had a habit of grinding. Now it's a turnkey classic. Last thing is an exhaust and he can stroll it around town! I'd better get this turbo car crackin soon!

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

I would get better push rods, stock bend pretty easy. Go with Comp Cam, custom grind they will/should recommend you valve springs & retainers for there camshaft and springs. S.B.C. valves fit right in your 6 head. Yes, new guides, (bronze type),retainers, (seals, Viton soft seal) keepers. Don't use the old school Teflon seals. All new & matching for your components. Stock lift is somewhere about .375" lift? .550" lift is a bunch more than stock. .500-520" lift is max I would go. Got any specs for a custom camshaft yet? You poor dad, gonna get spanked by your 6  Glad your pops car runs good., What was the HP & torque again? Don't forget the methanol injection! Need to save your cast pistons from detonation somehow.  Have fun.

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

I would get better push rods, stock bend pretty easy. Go with Comp Cam, custom grind they will/should recommend you valve springs & retainers for there camshaft and springs. S.B.C. valves fit right in your 6 head. Yes, new guides, (bronze type),retainers, (seals, Viton soft seal) keepers. Don't use the old school Teflon seals. All new & matching for your components. Stock lift is somewhere about .375" lift? .550" lift is a bunch more than stock. .500-520" lift is max I would go. Got any specs for a custom camshaft yet? You poor dad, gonna get spanked by your 6  Glad your pops car runs good., What was the HP & torque again? Don't forget the methanol injection! Need to save your cast pistons from detonation somehow.  Have fun. If I switch rockers later, will I have to rebuy pushrods assuming I buy better pushrods for the stock rockers? Also what length and what type pushrods should I get? Same as stock since I have stock rockers? Are the stock ones cast or steel? Because I found these and they're steel and should fit http://www.summitracing.com/parts/cca-7861-8/overview/ The closest thing I can find in chromoly is 9.7" long instead of the stock 9.682" http://www.summitracing.com/parts/cca-7659-16/overview/I called comp and lunati today. The guys at comp were kinda being dicks so I'm probably going to go with a lunati cam considering they gave a very similar recommendation. -219* intake/exhaust @ .5" -.5145" lift -114* lobe separation which sounded perfect to me. Only hiccup is Lunati said the installed height on the valve needed to be 1.85" for their associated spring with that cam. I just took the top half of the engine off today and am going to measure what the stock installed height is to see if I need to find longer valves for that spring. Do y'all happen to know the stock valve/spring installed height? When I call them back about the springs I'll ask them about the retainers and keepers. I'm going to keep going through beater blocks until I find the right combination of good power and reliability. Then I'm going to invest my money in the original block and get forged internals so that it'll last for the forseeable future. If I can get it to run well and not bust a $200 beater stock block, then I can swap in forged internals with the same setup and never have to worry about the pistons breaking again. Methanol injection will be after headwork and valvetrain but before internals. I'm wrapping up all the big things I want to do to it surprisingly. Got the turbo, fuel system, intercooler, and carb all done. Now I just have the big head machine work and later on meth injection and I'll be a happy camper. His car was 310hp and 410ft/lbs I think. But I think he has another 600lbs on me with that turbo 400 over my saginaw 4 speed and his big block over my I6. It'll be close.

Last edited by snowman4839; 05/14/14 02:38 AM.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

There is a hole slew of combinations that can be used for the springs/ retainers and loc's. Heck the loc's can come in different heights to help with installed heights.

Pushrods, best to measure after assembly and then order the correct length.

I would suggest pulling the rocker studs and machine for screw in studs and go to roller rockers. This also changes the pushrod length.

One thing to be cautious with on valve springs. Many times the cam company make a recommendation. They do not know ALL about the motor it is being used in. I have found the springs tend to "swim" around the valve guide and this is very bad for valve control. For your setup, the springs I offer fit the head right and will handle your lift and duration fine. They do not swim on the valve guide either.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Dec 2010

Posts: 535

Major Contributor

|

Major Contributor

Joined: Dec 2010

Posts: 535 |

Tom, I don't want to hi-jack this thread, can you PM me some information on the spring's you carry? I need to put new springs on my OHC engine and do not know yet what will and won't fit, heck I still need to look up the install height and diameter. I'm curious to see if the Chevy 250 uses the same size springs as the OHC and if so I may order up a set.

|

|

|

|

|

Joined: Nov 2012

Posts: 551

Major Contributor

|

Major Contributor

Joined: Nov 2012

Posts: 551 |

Yes you would probably have to but new pushrods again and the length will vary you have to measure them be checking the sweep of the rockers across the valve stem top

How many blocks have you been through now? Money wise might have been pennywise to have grabbed up some fordged pistons a while ago

Josh

72 gmc lwb air ride 5 speed (soon) turbo 292 II# 6102

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

the springs I offer fit the head right and will handle your lift and duration fine. They do not swim on the valve guide either.

I've emailed you about your head rebuild kit How many blocks have you been through now? Money wise might have been pennywise to have grabbed up some fordged pistons a while ago This is only my second one. When I can find running blocks locally for $200, it's a sound investment. The bearings and piston set alone would cost that much not to mention the time saved from rebuilding a bottom end.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Dec 2010

Posts: 535

Major Contributor

|

Major Contributor

Joined: Dec 2010

Posts: 535 |

[quote=snowman4839This is only my second one. When I can find running blocks locally for $200, it's a sound investment. The bearings and piston set alone would cost that much not to mention the time saved from rebuilding a bottom end.[/quote]

Yeah!! $200 beat on motor FTW!

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

[quote=snowman4839 If I switch rockers later, will I have to rebuy pushrods assuming I buy better pushrods for the stock rockers? Also what length and what type pushrods should I get? Same as stock since I have stock rockers? Are the stock ones cast or steel? Because I found these and they're steel and should fit http://www.summitracing.com/parts/cca-7861-8/overview/ The closest thing I can find in chromoly is 9.7" long instead of the stock 9.682" http://www.summitracing.com/parts/cca-7659-16/overview/I called comp and lunati today. The guys at comp were kinda being dicks so I'm probably going to go with a lunati cam considering they gave a very similar recommendation. -219* intake/exhaust @ .5" -.5145" lift -114* lobe separation which sounded perfect to me. Only hiccup is Lunati said the installed height on the valve needed to be 1.85" for their associated spring with that cam. I just took the top half of the engine off today and am going to measure what the stock installed height is to see if I need to find longer valves for that spring. Do y'all happen to know the stock valve/spring installed height? When I call them back about the springs I'll ask them about the retainers and keepers. I'm going to keep going through beater blocks until I find the right combination of good power and reliability. Then I'm going to invest my money in the original block and get forged internals so that it'll last for the forseeable future. If I can get it to run well and not bust a $200 beater stock block, then I can swap in forged internals with the same setup and never have to worry about the pistons breaking again. Methanol injection will be after headwork and valvetrain but before internals. I'm wrapping up all the big things I want to do to it surprisingly. Got the turbo, fuel system, intercooler, and carb all done. Now I just have the big head machine work and later on meth injection and I'll be a happy camper. His car was 310hp and 410ft/lbs I think. But I think he has another 600lbs on me with that turbo 400 over my saginaw 4 speed and his big block over my I6. It'll be close. [/quote] If you have any galling or erosion on the tips of your pushrods, they should be replaced.

You can reuse your stock pushrods, just check them out carefully.

Having greater valve spring pressure will tend to wear things out quickly if there are any defects.

Camshaft specs seem OK, but see if you can get a wider lobe center of 115-116 if possible.

Having forged pistons does not mean you cannot blow those up also like your last two engines. They just can take more abuse before they let go also.

Your dad will be surprised when you smoke him w/that V-8 of his.

What high octane are you going to use for your dual octane system?

How about for the low octane?

What are you going to do or use to keep the engine from blowing up on the low octane?

I do not remember if the intercooler seemed to help a lot w/power output on your 2nd engine?

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

If you have any galling or erosion on the tips of your pushrods, they should be replaced.

You can reuse your stock pushrods, just check them out carefully.

Having greater valve spring pressure will tend to wear things out quickly if there are any defects.

Camshaft specs seem OK, but see if you can get a wider lobe center of 115-116 if possible.

Having forged pistons does not mean you cannot blow those up also like your last two engines. They just can take more abuse before they let go also.

Your dad will be surprised when you smoke him w/that V-8 of his.

What high octane are you going to use for your dual octane system?

How about for the low octane?

What are you going to do or use to keep the engine from blowing up on the low octane?

I do not remember if the intercooler seemed to help a lot w/power output on your 2nd engine?

MBHD

Well isn't the length of the pushrods I use dependent on the valve height of the valve I end up using? I'm planning on using a lunati cam with TLowe's head rebuild kit. Wouldn't the only time the stock pushrods work is if the new springs were the same installed height? The guy at Lunati was concerned that I couldn't get that .52" lift out of the stock spring installed height. He was recommending I get a valve .2" longer and the associated springs. This makes sense because if the installed height is 1.65" (as per the chiltons manual suggests) for a stock spring and a stock replacement's bind height is 1.170", that means the max lift is only .486" which isn't enough for my cam. Unless Tom's kit has shaved retainers on bottom and raised top retainers to get that extra little bit of installed height needed. Really? Even a wider lobe center? Comp suggested 114*, Lunati said 112*. Tom's is 114* if I remember right? What advantage is there for a wider separation? I understand but if I get the engine to work borderline reliably then forged pistons and taking a degree or 2 out of timing will give me a reliable package not to mention the meth injection. Don't think of my system as a "dual" system. It's really a "switchable" system. I've been putting 93 in both tanks for the most part because I mostly like to get into to boost. I just have it setup like this so that in case I ever go on a long cruise with a lot of highway driving then I can throw 87 in the 20 gal stock fuel tank and cruise on cheap gas which won't hurt anything as long as I stay out of boost. But then I flip the switch and wait a few minutes, and I can run expensive gas for when I plan on getting into boost. I didn't notice a huge difference in the intercooler. All I noticed was it seemed to run better @ 15psi than it did non-intercooled at 10psi. Slight power increase from the increase in PSI but not a whole bunch else. I think the head is what's holding everything back now.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

[quote=snowman4839I do not remember if the intercooler seemed to help a lot w/power output on your 2nd engine?

Well isn't the length of the pushrods I use dependent on the valve height of the valve I end up using? I'm planning on using a lunati cam with TLowe's head rebuild kit. Wouldn't the only time the stock pushrods work is if the new springs were the same installed height?

The guy at Lunati was concerned that I couldn't get that .52" lift out of the stock spring installed height. He was recommending I get a valve .2" longer and the associated springs. This makes sense because if the installed height is 1.65" (as per the chiltons manual suggests) for a stock spring and a stock replacement's bind height is 1.170", that means the max lift is only .486" which isn't enough for my cam. Unless Tom's kit has shaved retainers on bottom and raised top retainers to get that extra little bit of installed height needed.

Really? Even a wider lobe center? Comp suggested 114*, Lunati said 112*. Tom's is 114* if I remember right? What advantage is there for a wider separation?

I understand but if I get the engine to work borderline reliably then forged pistons and taking a degree or 2 out of timing will give me a reliable package not to mention the meth injection.

Don't think of my system as a "dual" system. It's really a "switchable" system. I've been putting 93 in both tanks for the most part because I mostly like to get into to boost. I just have it setup like this so that in case I ever go on a long cruise with a lot of highway driving then I can throw 87 in the 20 gal stock fuel tank and cruise on cheap gas which won't hurt anything as long as I stay out of boost. But then I flip the switch and wait a few minutes, and I can run expensive gas for when I plan on getting into boost.

I didn't notice a huge difference in the intercooler. All I noticed was it seemed to run better @ 15psi than it did non-intercooled at 10psi. Slight power increase from the increase in PSI but not a whole bunch else. I think the head is what's holding everything back now. [/quote]

You most likely would use .100" longer valves, & normally you would use .100" longer pushrods, but you always need to check for proper length just to be sure.

I would go w/a wider lobe center to increase cyl pressure, you have low compression, better mileage & makes for a better driver IMO.

The intercooler will not make a huge difference in power in the lower boost levels, run 15-20 psi, that will definitely make a bigger difference in power.

You will notice a lot more power difference when injecting methanol over just using an intercooler, running both is just icing on the cake & an air to air intercooler does not have any moving parts & is pretty reliable.

Your cyl head & camshaft are really the big restrictions. Not just the head.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

You most likely could use .100" longer valves, & normally you would use .100" longer pushrods, but you always need to check for proper length just to be sure.

I would go w/a wider lobe center to increase cyl pressure, you have low compression, better mileage & makes for a better driver IMO.

The intercooler will not make a huge difference in power in the lower boost levels, run 15-20 psi, that will definitely make a bigger difference in power.

You will notice a lot more power difference when injecting methanol over just using an intercooler, running both is just icing on the cake & an air to air intercooler does not have any moving parts & is pretty reliable.

Your cyl head & camshaft are really the big restrictions. Not just the head.

MBHD

Well like I said I'm just going to get Tom's kit and work with that since I don't know much about it. I just asked the guy who's going to order it to change it to 115*. Speaking of rockers, I've found a lot of 7/16" roller rockers that aren't majorly expensive but they only have a ratio of 1.6. Could I use these and tell Lunati to work that into my cam by accentuating the more lobes to give me the same final lift. Or does it not work like that? I also found a set of 7/16" roller rockers from Comp that have a 1.75 ratio for a BBC. Shouldn't these be a simple swap after I machine the 7/16" studs in? 15-20psi? Sound like a challenge :-) Meth is another project for another time but it's on my to-do list don't worry. When I said head I was including the valvetrain but yeah. I got all that air/fuel mix pressurized and ready to go. Now I just gotta get into the engine haha. Just... wondering... when would the turbo I have become a restriction?

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

[quote=snowman4839

Well like I said I'm just going to get Tom's kit and work with that since I don't know much about it.

I just asked the guy who's going to order it to change it to 115*.

Speaking of rockers, I've found a lot of 7/16" roller rockers that aren't majorly expensive but they only have a ratio of 1.6. Could I use these and tell Lunati to work that into my cam by accentuating the more lobes to give me the same final lift. Or does it not work like that?

I also found a set of 7/16" roller rockers from Comp that have a 1.75 ratio for a BBC. Shouldn't these be a simple swap after I machine the 7/16" studs in?

15-20psi? Sound like a challenge :-)

Meth is another project for another time but it's on my to-do list don't worry.

Just... wondering... when would the turbo I have become a restriction? [/quote]

Cool on the lobe center.

Comp cam roller tip rocker arms BBC 1.75 rocker arms are good to use. No to the 1.6 rocker arm,,, Yes, 7/16 studs.

I think on your turbo,, it stated what the max boost it could handle, don't remember off the top of my head. Maybe 20-22 psi max?

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

I always use +.100" long SBC valves in all the lump heads I do. A stock length SBC valve is actually .050" shorter than the 250 valves, and you end up having to sink them too deep when going oversize and kill the airflow, so the longer ones keep you from having to do that and helps with the installed height as well.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

Looks like I might be getting some roller rockers since it'll probably be in the budget.

Just read up on break in procedure for a high lift cam and I read that it was recommended to lower the spring pressure back to stock or lower the rocker ratio a good bit for break in if open pressure is 260+ lbs which I'd imagine it will be. So since tom's kit's valves looked like a 2 piece valve, I'd need to remove the inner spring, then break it in, then find a way to remove the retainer and put the inner spring back in while the head is still on?

I looked the turbo up again. I didn't see a max psi. Just an intended hp range of 350-550hp.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Looks like I might be getting some roller rockers since it'll probably be in the budget.

Just read up on break in procedure for a high lift cam and I read that it was recommended to lower the spring pressure back to stock or lower the rocker ratio a good bit for break in if open pressure is 260+ lbs which I'd imagine it will be. So since tom's kit's valves looked like a 2 piece valve, I'd need to remove the inner spring, then break it in, then find a way to remove the retainer and put the inner spring back in while the head is still on?

I looked the turbo up again. I didn't see a max psi. Just an intended hp range of 350-550hp. Cool, what rockers did you find? Not too sure about running two piece valves? Those are normally lower quality. http://www.youtube.com/watch?v=OsGqmOQus6YI am not positive, but IIRC, most of those low cost china turbos do not use high boost I think @ the most 25 PSI, but don't quote me on that. You could ask the company you bought the turbo from, they might know. When you run out of compressor, you could always upgrade to a billet compressor wheel & or install a larger compressor wheel or just buy a bigger cheap turbo. MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

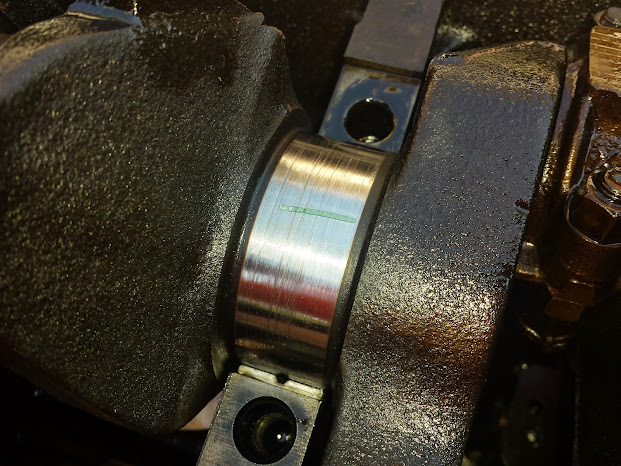

Found these rockers. Similar if not the same as what Tom offers but cheaper. http://www.amazon.com/Cams-1827-8-Magnum...er+rockers+1.75Do you mean 2 piece springs? I'm just going off of what it looked like from Tom's pictures. Tom's feel free to chime in on the specs of the valve from that head rebuild kit. Wow where can I get that spring compressor tool. That was the greatest thing I've ever seen. I'd ask that company but I haven't brushed up on my mandarin recently. It wasn't a huge deal. I just wanted to know at what point it would start to hold me back but it seems like I got a while to go. So... I had quite a day removing and tearing down the motor That is indeed a piece of the ring landing hanging off the side of the piston   Then a little further inspection made it a wonder how it was running in the first place. That is a main bearing with some pretty deep ridges in the center and it turned that bronze color from heat or excessive wear from lack of lube if I remember correctly.  Also scored up the crank bearing surface. Plastiguage showed clearances were .0035" so that would explain the 25psi maybe 30psi of oil pressure as opposed to the 45psi to 60psi from my first original motor.  Even the cam was starting to turn colors. I don't think I've ever seen this before. I'm guessing this too is from starvation causing excessive heat and wear.   I was planning on swapping a piston on this engine and give it another short run but after all that, it doesn't even seem worth it. Plus there's a pretty good lip near the top of the cylinder wall. TO BE FAIR! I never checked the bearings before I installed the turbo setup so this could very well be as a result from the mileage it had on it when I bought it.

Last edited by snowman4839; 05/15/14 08:38 PM.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Your previous post stated this. " So since tom's kit's valves looked like a 2 piece valve" That is where I got the 2 piece valve  Rockers look good!  There are different type of spring compressor tools, that one is cool though. You can make one also. Long, Flat plate steel, a hole for the rocker stud & a slot or bigger hole for the retainer, Bammm! Maybe? Hmmm, wonder what caused the ring land to let go? Cam is shot., bearings are worn, most likely high mileage, or not changing oil enough. Yes, debris going through the oil system causing grooves. .0035" is a bit much. That is probably not the only piston that is bad. But if you want to go through the trouble of throwing in a different piston & slap that engine back in,,, choice is yours.

MBHD Show some pics of the tops of your pistons. THX

12 port SDS EFI

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

Nasty looking piston!

My valves are one piece. The rockers you show are the same. The price on Amazon is for a set of 8. And price per part is 23.96

Mine is for 12 and are 23.33.

The bust ring lands are from the turbo abuse and not controlling detonation. As Hank said, even a forged piston can fail from detonation. You will want to address this with your next engine build.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

When I said 2 piece valve, I meant 2 piece spring. My bad. That's why I was asking about the spring compressor and how I would break it in with the outer spring only but then compress it and find a way to get the inner spring compressed when I put it on. But that compression bar using the stud seems like it'll work. I made one but it doesn't work with it out of the car because the whole head just rolls and I cant keep the head down even by standing on it to compress the spring. Should work fine with the head bolts in though. Well both the upper and lower compression rings had broken in addition to that chunk of side wall between them. Correct me if I'm wrong but that seems like the ring gap was too small and the amount of heat it was generating closed the gap to the point that they touched and expanded enough to break themselves and the lands around them. Plus I'd imagine the detonation pushed it over the edge. I'm not planning on rembuilding the engine on account of all the damage. The cuts in the surface of the crank were enough to make me forgo that. Plus now that I know there's a possibility of the new cam I buy being at any risk, I'll just stick to some other block. All the machine work needed is not worth it when I have that other good long block I can go buy. Again I'm not understanding why I would go buy a set of $600 pistons when again you guys say they're just as susceptible to breaking. I'd rather break a set of $100 pistons 6 times over the next 5 years than 1 set of $600 pistons in one year. Just notice that that set of rockers was only 8. I'll probably end up buying that set too Tom. I pressure tested all the pistons before I took the engine out. Everything was fine except for that one piston. IIRC, they were all at like 110-115psi except for one 95psi I think. Piston with the bad landing looked fine up top.  and so did every other one

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

I don't think anyone said they are just as susceptible to breaking as a cast piston, they are actually more tolerant to the increased levels of pressure, temperature and higher loads seen in higher performance applications like yours. But when things go wrong, and they can very quickly in forced induction apps, even a forged piston can suffer from the effects of detonation if not safeguarded with intercoolers, alky injection coolers and common sense.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

When I said 2 piece valve, I meant 2 piece spring. My bad. That's why I was asking about the spring compressor and how I would break it in with the outer spring only but then compress it and find a way to get the inner spring compressed when I put it on. But that compression bar using the stud seems like it'll work. I made one but it doesn't work with it out of the car because the whole head just rolls and I cant keep the head down even by standing on it to compress the spring. Should work fine with the head bolts in though.

Well both the upper and lower compression rings had broken in addition to that chunk of side wall between them. Correct me if I'm wrong but that seems like the ring gap was too small and the amount of heat it was generating closed the gap to the point that they touched and expanded enough to break themselves and the lands around them. Plus I'd imagine the detonation pushed it over the edge.

I'm not planning on rembuilding the engine on account of all the damage. The cuts in the surface of the crank were enough to make me forgo that. Plus now that I know there's a possibility of the new cam I buy being at any risk, I'll just stick to some other block. All the machine work needed is not worth it when I have that other good long block I can go buy.

Again I'm not understanding why I would go buy a set of $600 pistons when again you guys say they're just as susceptible to breaking. I'd rather break a set of $100 pistons 6 times over the next 5 years than 1 set of $600 pistons in one year.

Just notice that that set of rockers was only 8. I'll probably end up buying that set too Tom.

I pressure tested all the pistons before I took the engine out. Everything was fine except for that one piston. IIRC, they were all at like 110-115psi except for one 95psi I think.

Piston with the bad landing looked fine up top.

I doubt highly the ring gap was too small, the bores have a big ridge @ the top? Just for giggles, pull a couple rings off the piston, install one or a few in different bores about an inch down from the deck, (slide it down evenly w/a piston) measure your rings end gaps w/a feeler gauge. Let us know your findings

I am pretty sure if you have the other pistons examined w/zyglo or eddy current those, there are probably more cracks in the pistons, you just can't see it w/a naked eye. Those pistons you have there are 7.5:1 pistons, low, low compression, your original engine should have had a full point more of compression. Wise choice on not building that bad engine. As far as forged pistons, all piston are susceptible to detonation,, but,,,, with forged pistons, they can take a lot more abuse from detonation as compared to a cast piston, forged pistons are not bullet proof. I would just bite the bullet & break down & purchase some nice forged pistons, they will last you, but, only if you put some sort of muffler on your car, (so you can hear detonation) AT least get a MSD BTM ignition box . It cannot detect detonation, but @ least it can pull timing out when boosting & bring in more timing when under cruise & mileage is needed. MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

Im sure there are more of them broken as Hank is suggesting. Also by design, those pistons are never going to be up to the task of living in a blown app because the top ring is too exposed to the boost pressures and heat because of the huge chamfer on top. The custom forged pistons made for this type of application place the top ring well out of harm's way much further down the piston and protected by the full thickness of the ring land. Again, making it much more tolerant to the heat and abuse seen in force induction apps.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

So I just pulled the other pistons. They were all perfectly fine assuming there were no invisible cracks and whatnot. Closely did a 360 look of all the pistons and bent each of the rings some to see if they would fall apart. Everything looked peachy.

The ring gap though... wow. It was bigger than .035". I didn't have file gauges bigger than that. It was probably like .050"

Assuming my budget at the end of the summer looks good, then I might just send my original block off to get bored for a set of forged pistons... :-/ y'all might've convinced me. It still bugs me though that the main clearances were so tight in that engine with stock bearing replacements. I still don't understand how it could be that wrong.

Because that clearance is wrong, doesn't that mean I'd need to have the crank turned and by oversized bearing and hope I don't get the same problem?

Are there forged pistons that are swappable with the 250 pistons?

I saw Tom had some (I'm assuming the 250 is the 5.7" rod length) but they'd bring my compression up to 9.47 as it said on Tom's site. That seems pretty high for a turbo application.

Unless... try to follow me. Why do people use drop compression just to increase boost? It seems like if you want to go from a high compression motor (like 10.25:1) to a boost application you would just drop it to like 9.25 or 9.5 and boost it like 5-7psi instead of dropping it to 8.0 or 8.5 and boosting 15-17psi so then you don't have to worry about increasing the intake charge as much. Isn't the final compressed cylinder pressure what you're worried about? Like compression ratio * (14.7 + boost psi)? Why wouldn't they be the same as long as that formula balances?

Also Tom's were floating pin as opposed to press in. Does the wrist pin smaller than normal compensate or does the connecting rod end need to be enlarged?

Also I've never even thought to ask this. How do you choose whether to increase boost or timing? Because they both increase power but in a different way. Like how do you know if you've maxed out timing for that psi or if you've maxed out power in general. Because if I change the compression ratio, I wouldn't have a clue about timing or psi at 9.47:1.

Also how do engine builders and dyno shops know when they've reached max timing? Are they just that skilled at hearing knocking or is there like a rule of like back of 4* at any audible knocking? Or do they usually have knock setups to put into the engines while they're tuning them.

I'm gonna work on getting a knock sensor and then building a circuit to work with my microcontroller to buzz at me or light an LED or something when it gets a knock. I mean all it is a resistor that activates at certain frequencies.

Since that offenhauser intake mounts my carb sideways and makes my linkage on the wrong side and I realized that they make a 90* carb rotation adapter, is there any reason rotating it 90* so that he bowl points toward the front wouldn't work? Like something about the gas sloshing up against the metering block and jets messing up the mix or something. I know it sounds ridiculous but I figured I'd ask.

Last edited by snowman4839; 05/16/14 05:44 PM.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: May 2014

Posts: 40

Active BB Member

|

Active BB Member

Joined: May 2014

Posts: 40 |

Drop me a email at david@level-masonry.com

Snowman I got a ?

Xxxxxxx

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Snowman,

Boost is the result of putting more air/fuel into the engine.

Timing is just the control for temperature for peak pressure that a particular set up can take.

A knock sensor will kill power before you can make it. They will not work on a high performance engine just a junk stocker.

Turbo-6

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Snowman,

Just a FYI,

my friend is a distributer & friends with the owner for the J&S safe guard units.

He has built many high performance engines & has installed many J&S safe guard systems w/ knock sensors on many builds. They work great.

A knock sensor will save your engine, something you need since this will be your 3rd engine due to detonation you cannot hear & a knock sensor can.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

I understand what boost is. But how do people decide between compression ratio vs boost level?

And is 9.47:1 too much for a boost engine?

I'm not talking about buying a whole system like J&S to control my timing. I'm talking about creating something showing me direct output of a knock sensor. That way I can adjust my own timing accordingly.

Why spend $500 on something that will always pull my timing back to the same place when I can just save $450 and have something tell me where to pull it back to myself.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

There is a problem w/pump gas, the octane is not always the same, there are winter blends & summer blends of fuel.

You ever get a bad batch of gas? Car does not run like it did on the prior fill up of fuel?

Well, when this happens, if you set your timing on a tank of gas & you think everything is honky dory, but you get some bad gas, the octane is not what it is supposed to be, you go out & drive not worrying about your engine is going to detonate, because you already have it all set to run a specific boost & timing, well, you got that bad fuel, by the time you see it knocking , most likely it will be too late. The J&S will save your engine automatically.

You should read up again how the J&S system works or any factory knock retard system works. You do not know the concept. when you make a statement like this.

"Why spend $500 on something that will always pull my timing back to the same place when I can just save $450 and have something tell me where to pull it back to myself."

My A4 Audi has 10.25:1 compression, factory, it's turbocharged & it runs a decent amount of boost.

You want to know part of the reason why it can run that much compression? Electronics, they can pull timing when needed to save the engine.

More & more better electronics are available out there to help us make more power & save the engine at the same time, embrace electronics, dont knock them till you try them.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

snowman, a turbo adds cylinder pressure to the cylinders the same way compression does, so starting off with a high compression ratio to begin with just complicates things that much more. Most any stock engine can run 5 or 6 psi of boost without much issue, as the increase in cylinder pressure really isn't that much of a jump, but its enough to give you that warm fuzzy feeling. But when you start talking about boost levels in the 12-15 psi range, you are basically adding the equivalent of 3-4 compression points or more to the engine in the form of boost pressure, and as Hank and others keep pointing out, your not in Kansas anymore Toto! Everything has now changed from simple and inexpensive, to high end intercoolers and alky mist injection, to premium grade gas or better, high end electronics, $$$$ pistons, etc.... As Harry and others can attest, you can never overspend when building a high boost engine.

Many years before you were born and me too, there was a really smart guy that developed much of the concepts that power our nuclear industry. He became well known by also coining many phrases that we can make fit many different scenario's. One that I really like to mention, especially when it fits instances such as this is this.

"Insanity....repeating the same thing over and over again expecting different results!" Albert Einstein

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

MBHD - How do I not understand what the J&S system does? It listens for knock and retards the offending cylinder accordingly. I just read through and apparently it can build timing curves for each cylinder. Very cool but also very expensive.

What is wrong with me having a gauge just like the J&S system that has a light indicating knock and knock intensity? It'll go off if there's bad gas or it's a hot day or whatever and I'll know I either need to retard the timing or stay out of boost.

I'm not trying to attack you or anything. I'm just trying to fully understand how they're different if I'm willing to change the timing once in awhile on bad days.

CNC-Dude - I understand but what I'm asking is the tradeoff between boost and compression. Why do people prefer 25psi at 8.5:1 (212.5psi compressed) vs 18psi at 11.5:1 (212.5psi compressed) Wouldn't they make the same power and perform the same way?

The ONLY thing I can think of to trade off is intercooler heat extraction from the more compressed air making the high psi/low compression a cooler charge allowing for more room for improvement.

And is 9.47:1 to high or not??

Last edited by snowman4839; 05/17/14 03:51 AM.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

You could use a knock sensor & have it turn on a light or whatever, that is better than not having one. That would be great! I would personally like to run as much compression (for a turbo app) as possible & run less boost, why? Because this type of set-up would be a more enjoyable car to drive on the street, less turbo lag, better throttle response. But ultimately as far as making the most amount power, I believe if you run less compression & a lot of boost on top, that will net you the most power. But building such an engine for the street would be a dog, turbo lag up the ying yang,  , you really would not like it IMO, sure when boost comes in it will be crazy power, but off idle & mashing the gas pedal it will be disappointing.. My Syclone has 8.4:1 compression, it is lazy down low, plus that low compression will give you worse mileage. Snowman, If I were you, I would run a compression ratio of 9 - 9.4:1 & just plan on using a little bit less boost. When you build your short block, make sure you have the most & best quench area available. On my current engine my pistons come out of the block .002-.004" having done this allowed me to run 12.0:1 compression , this was a N/A engine @ the time. Just saying it is the utmost importance to have an excellent quench. http://racingarticles.com/article_racing-10.htmlWhen you run low compression, you can most likely run higher boost pressures. For the average consumer, (any person that will drive a turbocharged car, floor it, put cheap gas in the vehicle, drive it like they stole it etc, etc,,,) manufactures take this type of a driver into consideration when choosing an engines compression ratio. This is why you would see in the older turbocharged cars, they would run anywhere from 7.5:1 -8.4:1. With running that low of compression, the engines would have a fighting chance to stay alive & not detonate itself to death. Now, w/more modern turbo & supercharged engines, they run higher compression, why, better electronics, direct injection, (injector is located in the combustion chamber), higher fuel pressures of 2,200 psi instead of the old typical 40-60 psi. Timing Is Everything This adjustability in when the fuel is added to the cylinder is the holy grail of power production. Designers of early carbureted/distributor ignition and port fuel-injected/distributor engines only had one tuning variable that could be adjusted dynamically based on engine rpm and load: ignition timing (with counterweights on the distributor and a vacuum line from the intake manifold, respectively). Later port fuel-injected engines were developed with camshafts that could be phased (advanced or retarded) 20 or so degrees based on rpm and load. Now, DI allows the fuel application timing to be added to the cam phasing and ignition timing as another dynamic tuning tool. The DI fuel application is defined by two categories: fuel apply rate and fuel timing. MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

If you only shave the head enough to get a clean surface. This will not put the compression as high. The CC of chamber can also be adjusted by careful hand porting. I'd like to see around 9 to 1 for a street turbo engine. It will be more responsive. Just be careful to manage the timing and cool the intake charge. The J&S sounds like a great system. I know of nobody who runs one on a Chevy inline 6. Hank, you do it and show us. Snow, You need to come up with a timing setup that will monitor the boost and adjust/limit the timing. I have made vacuum cans in the past that will hook to a HEI and do this exact thing. One is installed on "PAPS" 32? ford with a supercharged 250. He won a Hotrod track race event in Kentucky with this car. Against V8's. LINK https://www.inliners.org/ubbthreads/ubbthreads.php?ubb=showflat&Number=41436&fpart=1

Last edited by tlowe #1716; 05/17/14 10:13 AM.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

I have the J&S unit in my Syclone working & functioning as advertised. Does not matter if you have a pancake 4 , inline 4, 6, 8 , v6, v8, etc, it will work on all those engines & more. I also have a new J&S for my inline turbo engine, whenever that will happen. Here are some videos for you to watch. http://www.youtube.com/watch?v=6o0NnDG7lXUhttp://www.youtube.com/watch?v=YM_DABUzGa8MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

I still want to see one hooked up on a Chevy 250 or 292 Inline. Not really sure where the sensor would be just "bolted" on.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Snowman, Adding air and fuel to increase pressure in an engine makes power, not just a higher compression ratio.

I would rather run 20 psi and less timing than something that changes your timing when it want's too.

Turbo-6

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

I still want to see one hooked up on a Chevy 250 or 292 Inline. Not really sure where the sensor would be just "bolted" on. You can bolt on a plate where there is a open 3/8 16 hole. Drill & tap the plate for a knock sensor. Or add a plate attached to where an engine mount goes. It's not rocket science, simple, don't make it sound difficult, because it is not. Anywhere on the block is fine, there are other alternate places also if you do not like those ideas. https://www.google.com/search?q=mounting...iw=1536&bih=720Also according to Douglas (in Brazil), the 250 Chevys were made until 1997. He showed me a picture of a stock 1997 Chevy 1500 pick up truck w/a 12 port MPFI 250 inline Chevy 6. I am pretty sure those later model engines had knock sensors from the factory. Anyone care to try & search that? I also would like to run the most amount of ignition timing run a bunch of boost & if knock is detected in one or any cylinders, I have a knock sensor system that can pull timing in the offending cylinder/s (AKA detonation) & make more power because it will be at the most available ignition advance possible, when the detonation goes away, the safe guard puts back in the timing for the engine to be at a safe operation & make the most available HP. Your engine will make more power if you can have more ignition advance (say 25 degrees, just an example ) & boost high, to say 20 psi, than you running 15 degrees advance & 20 psi. A J&S unit can provide your engine the most amount of ignition timing to make the most amount of power & be safer for your engine. The J&S unit has an adjustment on how sensitive the knock senor is. MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Strange don't see any Pro Mods running knock sensors.

Most race engines have so much noise i.e. piston slap, valve train

that the sensors don't work.

Just another electronic gadget to my way of thinking.

Turbo-6

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

You are correct. You also don't see pro mod running 91 octane & hoping it is really 91 octane & no water in it & run them on the street  I see what you are saying Harry, & no disrespect, but it seems most of your input is for race situations & on race cars or race cars used on the street. Maybe I am miss reading what you are saying? I do not think Snowman is making a full on drag car, unless I am misunderstanding what he wants to do to his Buick.  AFAIK, Snowman is not running C16, has loose forged pistons, solid cam & will be spinning the engine to 8000+ RPM The J&S unit has an adjustment on how sensitive the knock senor is.

12 port SDS EFI

|

|

|

|

1 members (53chevy),

146

guests, and

26

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|