|

|

Joined: Apr 2006

Posts: 831

Major Contributor

|

Major Contributor

Joined: Apr 2006

Posts: 831 |

Sell the 235 and buy a 250, you're a cam away from a great running engine, thought I'd throw that in before someone tries and talk you into a 4200

'45 Ford PU

66 Valiant wagon, leaning tower of power.

79 Chevy C10 w/250

02 PT Cruiser Convertable

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

Sell the 235 and buy a 250, you're a cam away from a great running engine, thought I'd throw that in before someone tries and talk you into a 4200  I'm not sure what I am going to do. Seems like the only people that want the 235's is the late 40's chevy truck guys. It's to nice an engine to scrap, but we will see, I can always put them on ebay too.

Last edited by GaryinMozarks; 10/06/12 07:23 PM.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

I was told that engine weighs as much as a B.B.C. , why would you want an engine that weighs that much w/hardly any output?  JMO MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Oct 2007

Posts: 5,052 Likes: 51

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,052 Likes: 51 |

A '57 wagon with a turboed 235 would be a unique and fun car to drive. If you are driving and having fun it would be fine. If you are going to build a race car it won't be fun very often.

Last edited by Beater of the Pack; 10/07/12 01:19 AM.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Sep 2008

Posts: 3,674 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,674 Likes: 42 |

Sell the 235 and buy a 250, you're a cam away from a great running engine, thought I'd throw that in before someone tries and talk you into a 4200  I'm not sure what I am going to do. Seems like the only people that want the 235's is the late 40's chevy truck guys. It's to nice an engine to scrap, but we will see, I can always put them on ebay too. Yeah, the 235's are decent upgrades for the guys that have 216's in the older cars and trucks, but they are heavy, and upgrading to a 250 or 292 is well worth the effort if you are looking for a more modern alternative. Plus, there are guys on the Stovebolt forum that give away the 235's all the time for free, so I wouldn't expect anything spectacular from ebay if you try to sell it.

Class IV CNC Machinist/Programmer

|

|

|

|

|

Joined: Aug 2003

Posts: 1,905

1000 Post Club

|

1000 Post Club

Joined: Aug 2003

Posts: 1,905 |

I got my running 292 free over on Stovebolt. Just had to go to MD to pick it up. I know. Lucky.

Drew

Mid-Atlantic Chapter

|

|

|

|

|

Joined: Jan 2010

Posts: 493

Contributor

|

Contributor

Joined: Jan 2010

Posts: 493 |

With a turbo, dont you just "dial-up" the performance you want?

The whole idea of wasting a turbo on a six is to make a fool of folks, aint it? 'cause you can sure put one on a V8 and really go to town.

So putting a turbo on a 216-261 series should be a bigger kick yet. You can homemake the special intake (if you want a special intake) easier since they are round to match round tubing.

Their lower ends are a bit weaker with only 4 mains (and only a 3.9375" stroke) instead of seven (4.12" stroke on the 292)--but you sure cant deem them weak, they were originally sized for use with heavy CAST IRON PISTONS. The same bearing area has sucessfully supported aluminum pistons .375" oversize (.125" over 261 @ 3.875") You're not running these things flat out every moment.

You want weak, go with an all out 296 ford flatmotor with their THREE main brgs.

Turbo'd stovebolts ought to be the berries.

|

|

|

|

|

Joined: Oct 2007

Posts: 5,052 Likes: 51

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,052 Likes: 51 |

To keep from totally hijacking this thread somewhat related thoughts are in a new thread called " Inline Evolution." It's a matter of taste and purpose.  Beater

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

With a turbo, dont you just "dial-up" the performance you want?

The whole idea of wasting a turbo on a six is to make a fool of folks, aint it? 'cause you can sure put one on a V8 and really go to town.

So putting a turbo on a 216-261 series should be a bigger kick yet. You can homemake the special intake (if you want a special intake) easier since they are round to match round tubing.

Their lower ends are a bit weaker with only 4 mains (and only a 3.9375" stroke) instead of seven (4.12" stroke on the 292)--but you sure cant deem them weak, they were originally sized for use with heavy CAST IRON PISTONS. The same bearing area has sucessfully supported aluminum pistons .375" oversize (.125" over 261 @ 3.875") You're not running these things flat out every moment.

You want weak, go with an all out 296 ford flatmotor with their THREE main brgs.

Turbo'd stovebolts ought to be the berries. Yep something like that. I don't know that I would call putting a turbo on a 6 "wasting" it. as a v6 and a straight 6 arn't that much different. And then there are the turbo 4's The thing is, everyone into tri-five chevys poo poo the poorly 6 and Id like to have something that would wake em up a bit. As I understand it, yes, I can dial in the boost I want but I don't want a lot, Maybe 5lbs boost. Just enough to make it a good cruser.

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

Well we are making progress, I bought a 80 buick turbo unit. It should be here Monday. Then we can start figuring out how it goes together.

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

I got the turbo yesterday. I am excited.

It looks good and the turbine spins freely with no noticable play.

Now I have to figure out what is necessary to stay and what needs to go.

There are a dozen vacuum ports that I have no idea what to do with other than plug em and see. I see one large square port that needs a plate made to cover it.

It looks like there are two water ports, in and out, below the carb. Is that correct?

It looks like the oil just drains out of the turbine back into the engine. correct? IF that is so, I will have to hook up some kind of line and feed it back into the engine where the oil filter drains.

I ordered a 3/4 x 4 x4 aluminum plate from speedy metals to make the adapter plate from the intake to the compressor exhaust. It should be here wednesday or thursday.

Any insights would be appreciated.

Gary

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

Oil drain at least 1/2" ID, must go downhill the entire length (no rise, no level span), end in the pan well above the stock oil level.

I have no idea how much oil must be diverted to the cartridge, I've heard 30 psi is enough and the original fitting works OK as a restrictor, but not sure where to take it off the block.

|

|

|

|

|

Joined: Apr 2006

Posts: 831

Major Contributor

|

Major Contributor

Joined: Apr 2006

Posts: 831 |

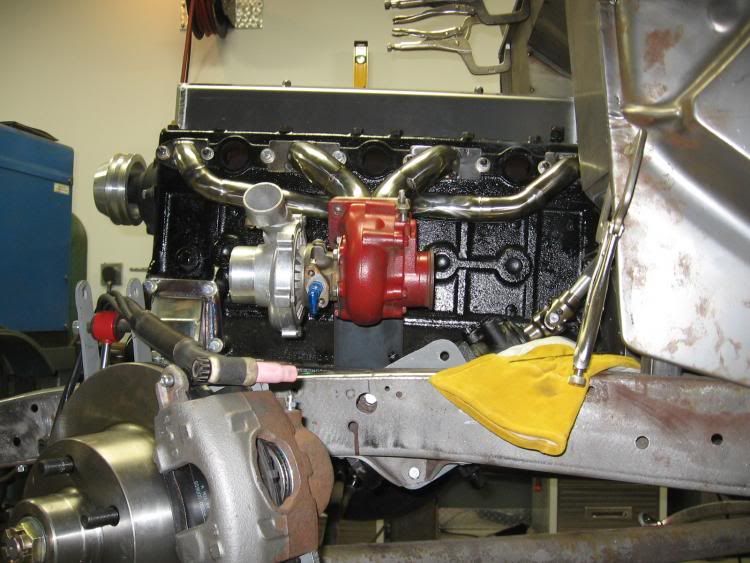

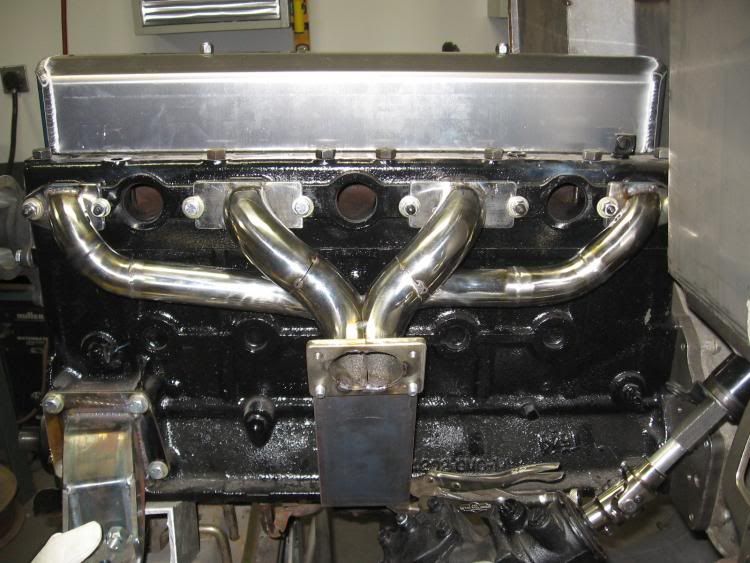

If you ever decide to go to a T3/4 style here's a 302 Jimmy turbo manifold,  ,  ,

'45 Ford PU

66 Valiant wagon, leaning tower of power.

79 Chevy C10 w/250

02 PT Cruiser Convertable

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

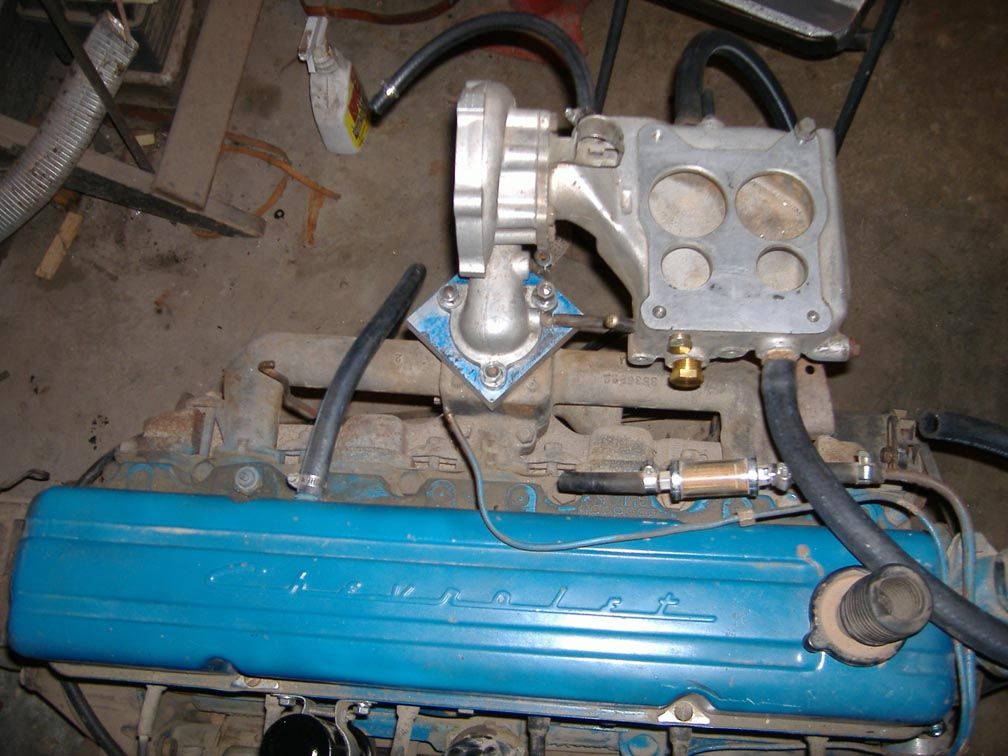

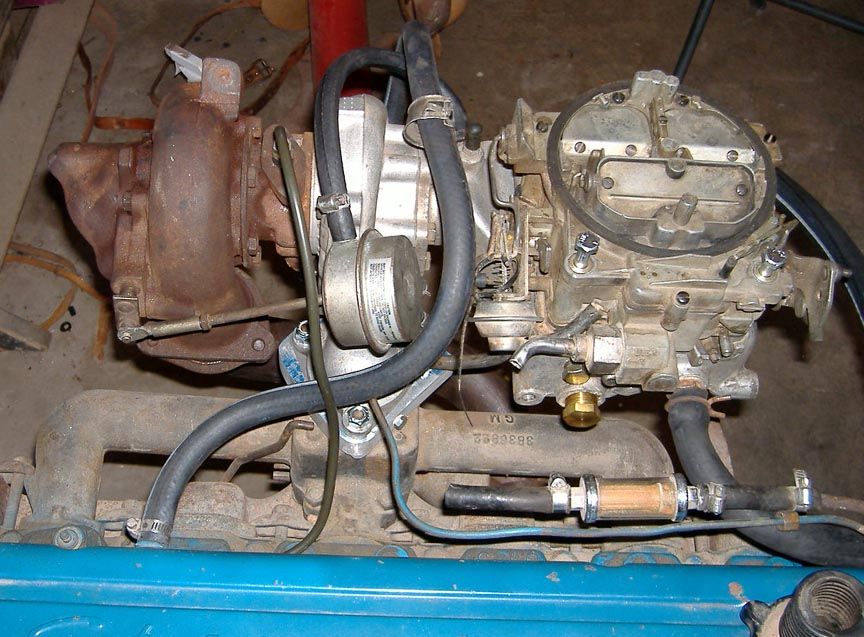

Making a little progress.

I have a 73 quadrajet that I think will work fine. I have to convert the choke from a manifold choke to a electric choke, but I think thats doable.

I figured out how to clock the turbo to keep the oil inlet on top and the drain on the bottom, and the pipes where they need to be.

Still awaiting the aluminum to make the adapter.

what am I forgetting?

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

I got the block to make my adapter. I got the plenum plumbed for water and ran the oil supply line to the turbo. I have to come up with a way to drain the oil. I am thinking of welding a 1/2 inch tube to the oil pan just below the top sorta like a dip stick tube. Any reason that won't work?

I wish I knew how to post pictures on here. I took some.

Last edited by GaryinMozarks; 11/14/12 01:46 PM.

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

I think I got it figured out. Here is my turbo mounted on my 235 engine.  der="0" alt="turbo top"></a>  I will take more pictures today of the adapter plate and the plumbing

Last edited by GaryinMozarks; 11/15/12 12:52 PM.

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

I got the adapter made today.

|

|

|

|

|

Joined: Oct 2007

Posts: 5,052 Likes: 51

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,052 Likes: 51 |

That is looking really cool. That thing is going to kick some butt. Simple and neat,

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Nov 2012

Posts: 98

Active BB Member

|

Active BB Member

Joined: Nov 2012

Posts: 98 |

'71 Chevy Shortbox 250ci

'99 Jeep TJ 242ci

Inliner #5787

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

That is looking really cool. That thing is going to kick some butt. Simple and neat, The credit for the setup goes to Tom Lowe. He was the one that suggested it and explained how it worked.

Last edited by GaryinMozarks; 11/15/12 11:53 PM.

|

|

|

|

|

Joined: Apr 2010

Posts: 6

Active BB Member

|

Active BB Member

Joined: Apr 2010

Posts: 6 |

This is a very cool setup Gary, I look forward to seeing the performance!

|

|

|

|

|

Joined: Apr 2004

Posts: 3,569 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,569 Likes: 37 |

Your doing the hard work. You get the credit. This is going to be cool to see running.

Wish I had time to make the adaptor for you.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Apr 2010

Posts: 6

Active BB Member

|

Active BB Member

Joined: Apr 2010

Posts: 6 |

You might look for NOS Stellite Exhaust Valves for your 235! I will tell you that there were people running a turbo on a 216 with good results, but at most 6 lbs boost. This is a good project..

|

|

|

|

|

Joined: Apr 2010

Posts: 6

Active BB Member

|

Active BB Member

Joined: Apr 2010

Posts: 6 |

|

|

|

|

|

Joined: Oct 2007

Posts: 5,052 Likes: 51

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,052 Likes: 51 |

Make sure your lines to the waste gate actuator are on the correct sides so excess exhaust is dumped into the exhaust pipe and boost is controlled. Remember more air needs more fuel. If it's too lean the pistons melt..If your set up was OK when you got it it should be a good starting point that you can tune to your needs. Thanks for sticking with it and for sticking with the 235.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

Here is the adapter mounted

|

|

|

|

|

Joined: Oct 2007

Posts: 5,052 Likes: 51

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,052 Likes: 51 |

That is actually a better idea than the modifications I made to my stock manifold.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

I got the gaskets made. I don;t know if they have to be exceptionally thick. I made them oout of some medium gasket material I had here. I got the unit bolted down and plumbed. I still haven't got a good way to get the oil back into the pan. I am thinking of removing the pan and welding a 1/2 inch tube just below the lip of the oil pan angled up. Next I have to make the manifold pipe from the exaust to the turbo and the downpipe. Here are some pictures.

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

The drain can go to anyplace on the engine that's lower than the bottom of the cartridge.

This may include your pushrod compartment cover, timing cover, and (if you're using an electric pump) your fuel pump opening.

Farther down is better, so if it's not too much below the turbo make the line big.

I would attach a fitting permanently to the sheet metal with a 1/16" doubler (inside for appearance), like a bulkhead fitting with an O-ring, and a compression fitting or hose barb to accept the end of the drain hose so you can take it apart without getting everything wet.

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

Made a little progress, I got my frame up from out back to use as a test stand. Spent 4 days sandblasting and painting it. Got the engine mounted yesterday and today I made the blockoff plate for the EGR and mounted the radiator. Im concerned that it all won't fit under the hood.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Looking good.

Looking @ the pics, I do not think your wastegate actuator is hooked up correctly.

I am thinking the wastegate actuator hose hooks up to the nipple on the compressor outlet, the 3 bolt flange, so it will see boost pressure. Where you have it hooked up, it will only see vacuum.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

Looking good.

Looking @ the pics, I do not think your wastegate actuator is hooked up correctly.

I am thinking the wastegate actuator hose hooks up to the nipple on the compressor outlet, the 3 bolt flange, so it will see boost pressure. Where you have it hooked up, it will only see vacuum.

MBHD I'm not sure, but I think the hose you are seeing is the outlet for the wastegate actuator. It goes into the lower half of the actuator. Its hard to see in the picture becasue of the way the compressor is clocked, but there is another short hose that comes from the compressor outlet to the upper half of the wastegate actuator on the other side. Gary

Last edited by GaryinMozarks; 11/28/12 12:52 PM.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

[quote=GaryinMozarks

I'm not sure, but I think the hose you are seeing is the outlet for the wastegate actuator. It goes into the lower half of the actuator. Its hard to see in the picture becasue of the way the compressor is clocked, but there is another short hose that comes from the compressor outlet to the upper half of the wastegate actuator on the other side.

Gary [/quote]

OK, hard to tell from the pics.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

In this pic from a diferent unit you can see the hose. Its alot shorter now due to clocking

Last edited by GaryinMozarks; 11/29/12 12:32 AM.

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

Can anyone tell me if the turbo outlet gasket for an 80 Buick turbo is a donut or a flat gasket and maybe a part number?

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

I found a gasket for the turbo exit. The last week has been taken up with little things needed to get it running, that take so much time. Made a new vacuum line, hooked up the boost gauge even though I plan on getting it running without the turbo first. battery and new battery cables. Finished up the exhaust. Had to rebuild the soleniod for the starter. Hopefully it will run soon.

|

|

|

|

|

Joined: Jun 2011

Posts: 33

Active BB Member

|

OP

Active BB Member

Joined: Jun 2011

Posts: 33 |

Hey guys,

Slow prgress, but I got through the Christmas travel bit, and back at it. I got a 4 ft lockar throttle cable and the carb bracket, plus I got a walker 2 1/2 inch muffler. Still waiting for the pedal to arrive.

I had to replace the water pump and rebuld the solenoid. I had to remove and solder the radiator.

Yesterday I dragged an old bumper up from the barn to mount on the farme so I can hook up an old U-haul tow bar and take it into town to have our local exhaust guru make the up and down pipes for the turbo.

I still havn;t gotten it running yet. When I picked up the engine to set it in the frame, I used the rear head bolt to lift it. The washer I had around the bolt slipped and bent one of the pushrods, which i replaced, but I think I have it to tight. I get a poping back through the carb. I am going to have to loosen it up and check the timing.

I'm working on it outside and its turned off cold and snow, so I may postpone it till it warms up a bit.

|

|

|

|

0 members (),

86

guests, and

36

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|