|

|

Joined: Jun 2007

Posts: 1,411

1000 Post Club

|

1000 Post Club

Joined: Jun 2007

Posts: 1,411 |

Can you see through one hole (with light shining through he other)?

If so how far away is the diaphram from those holes?

If you have the room to drill and tap them for plugs, you probably have the room to tap one for a fitting.

If you want to put the reference line elsewhere you can cover those holes with a piece of rubber and run a larger hose clamp around the pump.

My, what a steep learning curve. Erik II#5155

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

That's a good idea of clamping rubber on it. I'll probably just drill lower to be safe.

Now here's a new problem. I started to do the basic turbo setup on my current engine tonight and got the carb and manifolds off. Test fitted the pipe and I have a big problem. I don't have any way to get the uppipe to be where I need it without almost making a straight 90 degree angle out of the manifold to get it over the frame rail. My only other option besides that is running a very long tube under the frame rail. So would the 90 degree angle (can't really even be a bend) or the very long tubes be ok?

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Pics would help a lot so we all can see what you are talking about. Even a short vid on you tube or? You can run a long tube. Some, STS sytems have the turbo a long ways back from the engine compartment. http://ststurbo.com/The turbo is far away & they still make a lot of power. here is an STS 04 GTO http://www.youtube.com/watch?v=izQgzlrDq20I have suggested to run a exhaust pipe to the passenger side & place the turbo on the passenger side if you want more room. I am not suggesting for you (snowman) to run a set-up like this, it's more complecated & costs more. http://www.youtube.com/watch?v=xnFA93_U9hYLots of options. MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Snowman,

Run the turbo on the hot side (exhaust) spins the turbo best, then run the pipe from the turbo to the intake however long as needed, the long length helps slow and cool the charge and makes a bigger volume of air ready for the engine to suck in when the throttle is opened.

Remember turbos don't make air move faster, they only make it more dense, more oxygen per volume.

Harry

Last edited by Turbo-6; 10/08/11 01:35 AM.

Turbo-6

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

I don't really want to run a tailpipe turbo and to have it ru. To the passenger side, I'd just have to take it to a muffler shop and have them bend the pipe which I would only really want to do if all else fails. The problem with running the turbo almost right off of the manifold is I wouldn't have anywhere to put the wastegate. Well this is the best I can do for now. The plan is to (using the perspective from the picture) run the pipe in a 90 degree bend out of the manifold over the frame rail then use a little pipe to move it out from under the manifold and then do another 90 degree bend so that its pointing up now and sitting to the right of the alternator. Then weld the flange on there and have the turbo sit right behind the manifolds to the left of the frame rail and to the right of the alternator. I hope that made sense. The spacing issue is that I have about 4 inches from the lowest point of the frame rail to the outlet of the exhaust. So that'd have to be a pretty tight curve out of the manifold.

Last edited by snowman4839; 10/08/11 02:00 PM.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Feb 2010

Posts: 136

Contributor

|

Contributor

Joined: Feb 2010

Posts: 136 |

I had to turn mine really sharp. It can be done. Use as big as diameter as you can, mandrel bends. Measure and mock up is very important. I have very little clearance with mine. Probably less than 1/2". It can be really close, just as long as it does not rub with movement and vibrations.

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

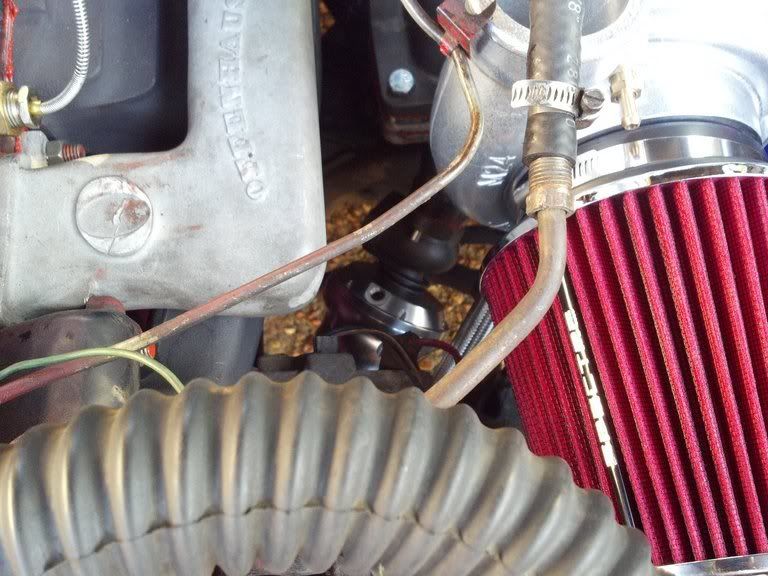

Mine is pretty similar to yours boucher but I couldn't run mine below the frame rail. Because I'm a boss and amazing at everything, I worked for about 4 hours today getting the manifold bolts converted to studs, getting the new manifolds put together and put on, and getting most of the uppipe put together. My buddy kept stressing to me to try that pipe I already made but I was reluctant since I knew it was too tall. So All i really needed to do was cut off a bit on the top to make it a little shorter and then it fit just fine. All I have left to do is final weld and put the flange on. I have had the flange on and the turbo positioned and it fits fine but my tack was very weak and it fell off. Here it is tacked together.  Decent amount of clearance between it and the frame  Pic of it out of the car  I ran into a pretty big problem putting the manifolds going together. The "heat riser" (I guess it'd be called?) hit the 292 manifold in a few places on the 1st and 2nd/3rd runners. Mainly on the 2/3 runner  But I ground it down and it seems to have sealed well  Then another problem is that the manifolds weren't flat at all. I hope they straightened out after being torqued down but the 4/5 exhaust manifold runner was too far back about 1/8"

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Snowman,

I was going to say from the first pic, it looked like you have plenty of room to work with, & it seems you found a way to have enough room.

Where the heat riser section bolts to the intake manifold.

I would run a block off gasket, that exhaust manifold is going to heat up your intake manifold, real fast & at a higher temperture.

You are going to get a lot more underhood heat you will want to some how get rid of that heat.

Running a turbo gives you so much underhood heat ,you would probably want to run a hood vent or fender vents.

I do not think you will do that type of mod/s to your car, just saying.

You could send out both of your manifolds to get surfaced evenly to give you a better seal.

From the pic of your exhaust pipe, are you going to mount the T4 flange to the jagged secton?

If so, I would not mount the turbo that low, if you could move it up & a bit more forward I would think that would be a better position for your turbo..

You are doing good, keep it up!

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

I probably will block off that heat riser when I put it on the other engine.

Before I jump to getting the manifolds resurfaced, I want to see if I have any vaccuum/exhaust leaks that would make that necessary.

For underhood heat could I take out one of my front high-beam headlights and run a pipe from that hole to blow on my turbo? That would almost give the effect of a cold-air intake since the cooler outside air would get sucked into the compressor too. That's the only simple way I can think to ventilate it.

Yes. The T4 flange will be welded to the end of that pipe. It looks jagged because I flattened out those sides so that it would match up to the flange.

It's not really that low. The top of the turbo is about level with the top surface of the exhaust manifold.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Snowman, if you have an 1/8" gap, I would think it will leak. But like you said, I guess, try it out. Maybe you need to open up or slot the 4 holes on the intake manifold where the exhaust manifold bolts up to?

This will allow the exhaust manifold to center up flush w/the intake manifold flange.

Might need to trim/grind on your intake & or exhaust manifold where it was hitting before.Yes, you can take out 1 high beam headlight for cooling & maybe ramair to the turbo? The other problem is trying to let out the excessive underhood heat, that is why I suggested a hood vent or fender vents. Example: http://cgi.ebay.com/ebaymotors/70-81-CAM...=item56466275cb Hood vents: http://cgi.ebay.com/ebaymotors/68-69-Cam...=item4840ded97dAs far as turbo location, make sure you have enough room all the way around the turbo, the stock 6 cyl mounts move excessively, also, if you install a physically larger turbo, you will have room for an upgrade if you are wanting to do so later-on down the road. Also, make sure the oil drain line from the turbo is high enough & will put the drain line @ a good angle to drain back into your oil pan.MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

Just a couple of questions about vacuum/boost lines.

Does it matter what type of line I use?

What is the difference between using the manifold vacuum ports, the accessory port on the carb (which should be manifold vacuum), and the nipple on the compressor?

What should be hooked to the boost gauge?

What should be hooked to the fuel pump?

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Feb 2010

Posts: 136

Contributor

|

Contributor

Joined: Feb 2010

Posts: 136 |

I just used rubber vacuum or windshield fluid lines. 3/16".

I have a air cleaner spacer (above the carb) that I have tapped twice. One for a boost gauge and other for boosted fuel pressure. Because its above the carb / throttle plates, so I only see boost on the gauge, no vacuum.

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

Well I have a sunpro vacuum/boost gauge so would I connect that to the large accessory port on the carb that links to manifold vacuum? And since the fuel pump only needs boost, I could attach that to the nipple on the turbo right?

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

Now your getting it.

I like the use of the vacuum gauge, great to help tune with.

Manifold for the Vac can on dist too.

Wastegate hooked to carb hat. Do you have a Blow Off Valve?

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Does it matter what type of line I use? Yes, purchase some nice silicone vacuum hose as I stated before. Do you take notes or read all the posts?  pg. 24 Previous post :#66525 "Also, for the hoses to run you wastegate & B.O.V. (blow off valve), run some nice silicone hoses, not rubber. pg. 24 Previous post :#66525 "Also, for the hoses to run you wastegate & B.O.V. (blow off valve), run some nice silicone hoses, not rubber.

Also, the sense line for your FP (fuel pump) silicone hose also."

Regular rubber will crack & is affected by heat, silicone, much better product.What should be hooked to the boost gauge? Direct to the manifoldWhat should be hooked to the fuel pump? Carb bonnetMBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Snowman,

pics or video on progress?

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

Decent amount of work done. Cut the up pipe a little short before the t4 flange so it sits a little low and barely rubs on the upper a arm. Ordered another .5" t4 flange to put on top of the one welded onto the pipe to act as a spacer. Got the wastegate welded to where it is almost perpendicular at the bottom of the U on the up pipe which should be awesome for flow. Got the feed line ready and need to drill the hole for the drain line. Carb/intake/exhaust are all on and all good. New carb linkage I made works great. All that's left is just finishing mounting the turbo, doing the intake lines/BOV, drain line, and exhaust dump or out the back.  Don't worry the flange/wastegate don't hit the steering.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Snowman, it sounds like you have the wastegate pipe @ a 90 degree angle off of the 2.5" feed pipe to the turbo? Hard to tell, no good pic of the wasegate pipe. If so, that is not good for exhaust flow, it will probably still work, but it's not ideal. Hard to tell, do you have room to install a wastegate pipe onto the wastegate? Do you plan on using a pipe for your wastegate & merge the wastegate pipe into your exhaust system or run a separate pipe w/a mini muffler or? Not sure if you got an intercooler, can't remember. If not, get one. Do not just run a short pipe from the turbo to your carb bonnet, you really need an intercooler. This CO. has a lot of cheap$$$ intercoolers: http://cgi.ebay.com/ebaymotors/25-x12-X3...=item3a6771ce68intercooler pipe kit: Just some examples: http://cgi.ebay.com/ebaymotors/2-5-BLUE-...=item336c0970c9http://cgi.ebay.com/ebaymotors/3-UNIVERS...=item5645a69727It's looking like a fun project & more like a turboed engine, keep it going. MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Feb 2010

Posts: 136

Contributor

|

Contributor

Joined: Feb 2010

Posts: 136 |

Snowman,

Not sure if you got an intercooler, can't remember.

If not, get one.

Do not just run a short pipe from the turbo to your carb bonnet, you really need an intercooler.

MBHD MBHD, not to sound like I am in disagreement, but Why and Intercooler? I have almost the same set up as Snowman. I am running a short intake pipe directly from the turbo to the carb without an intercooler. I have read from the turboforum that intercoolers are much more useful in fuel injection systems but not as much in blow thru applications. I read that the fuel entering the system cools the charge down quite a bit. I have put over 300 miles on my truck this week without any problems. Many WOT runs with no detonation, smoke, issues. Boosts will rise to 10psi, when I let off it creeps to 11 psi. The only thing that is barely noticeable is that it seems to run a bit peppier when first warmed up. Once the engine bay is fully heated (heat soak) it seems just a little doggish. But not enough to go changing things. The reason I am so inquisitive is that I am considering clocking my turbo and putting a intercooler system on this winter. I want to get straight answers before I go to the effort and $$$. By adding an intercooler what would I be gaining? Keep it up snowman. Its all worth it once you blow thru! Boucher

|

|

|

|

|

Joined: Oct 2011

Posts: 28

Active BB Member

|

Active BB Member

Joined: Oct 2011

Posts: 28 |

Not meaning to hijack, but Boucher what size pipe did you use?

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

MBHD, not to sound like I am in disagreement, but Why and Intercooler? I have almost the same set up as Snowman. I am running a short intake pipe directly from the turbo to the carb without an intercooler. I have read from the turboforum that intercoolers are much more useful in fuel injection systems but not as much in blow thru applications. I read that the fuel entering the system cools the charge down quite a bit.

I have put over 300 miles on my truck this week without any problems. Many WOT runs with no detonation, smoke, issues. Boosts will rise to 10psi, when I let off it creeps to 11 psi. The only thing that is barely noticeable is that it seems to run a bit peppier when first warmed up. Once the engine bay is fully heated (heat soak) it seems just a little doggish. But not enough to go changing things.

The reason I am so inquisitive is that I am considering clocking my turbo and putting a intercooler system on this winter. I want to get straight answers before I go to the effort and $$$. By adding an intercooler what would I be gaining?

Keep it up snowman. Its all worth it once you blow thru!

Boucher Boucher, good question, especially when most car magazines turbo books (in the past), etc, say when you boost only to 6 or so psi, there is no reason for an intercooler. Now comments stateing an intercooler is not needed/necessary is coming from turbo gurus of the past making these type of statements, I never listened to them or believed them. Just me I guess. I say BS, anytime you can cool your intake charge,, DO IT!  Even @ a low boost of say 6 psi, you will be surprized just how hot the turbocharger heats up the air. I know you can run w/out an intercooler I have done so running a Paxton supercharger running close to 10 PSI of boost w/8.5:1 compression ratio on pump gas. I always planned to run an air to water set-up for it, just never got around to installing it.  Not sure who posts that an intercooler is not for a blow through carb set-up,? but I would say, don't listen to those people. You state when your truck gets heat soaked it seems a little doggish, well w/an intercooler, it gets less heat soaked & for the most part will still run good even after the engine is all warmed up. You will noticed,, especially during cold winter day or even just a cool night, when you drive during the day, your truck will run pretty good, well when you add an Air to Air intercooler & drive on a cold day or cool night, you will say to yourself, this turbo engine really runs ALOT better on a cool or cold day/night. I will promise you, after you install an intercooler set-up, you will ask, why didnt I install this in the first place? After you install an intercooler: You will make more power, you will be able to advance your timing. Better mileage. If you notice the first Grand Nation/T-Types (IIRC 1984-1985) are called hot air car, meaning, there is no intercooler. Look @ the 86 & 87 Buick GN's & T-Types, they added an intercooler & other odds & ends (improvements) adding an intercooler allowed them to turn up the boost ,made more power & was the fastest Car GM produced those years. Both the hot air car & intercooled cars were fuel injected. On my Syclone running 18-19 psi 9 degree day the intake temps gets up to 120-130 degree F, that is w/a stock air to water intercooler. I would say if the Syclone did not have an intercooler, temps would be so high @ 19 psi I would need to run race gas. Usually w/an Air to Air intercooler your intake temps will go down during a 1/4 mile blast (dependant of size intercooler) Nowadays w/so many cheap (money wise) China intercoolers on ebay, there is no good reason not to add an intercooler. A decent intercooler & plumbing is how much? Just an example: http://cgi.ebay.com/ebaymotors/25-x12-X3...=item3a6771ce68Then buy a plumbing kit: http://cgi.ebay.com/ebaymotors/3-UNIVERS...=item4cf587e2d0Together you spend: $232.00 ,years ago you would have to buy a Spearco core or simular, high priced unit, buy the end tanks get it all welded together & cost $1000.00- $1500.00 depending on core size, but you get my point, buying a intercooler years ago installing an intercooler & plumbing would be crazy high dollar ammount & most people would not get them because of costs. Bar & plate designed intercoolers are beffy & heavier than a tube & fin design. That is what I purchased, a bar & plate intercooler. IIRC, price was about $220.00 when I bought it. This is the same size: http://cgi.ebay.com/ebaymotors/ws/eBayIS...984.m1423.l2649But nowadays, like I said before, no reason not to run one & yes you will see an improvement. Boucher, install an intercooler,you will be happy you did & tell us about your results. B.T.W., never heard about how you got your black exhaust smoke during acceleration resolved. Also, if you do not get any detonation @ 10 psi, add an intercooler & run 15 psi , & watch the smile on your face get even bigger.Is the T5 shifting better? Hope this helps. MBHD PS, I do not know if Tlowe took any turbo outlet temps (on his makeshift turbo 250 dyno test) @ only 6 psi ?, but IIRC, he did say it was very, very hot air coming out of the turbo & that was only @ 6 psi.

12 port SDS EFI

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

No did not take any intake temps. Will say this, after a run on the dyno, you could not hold your hand on the discharge line. Not that it would burn you, it was just hot enough that it could not be held. This was at 5 PSI.

A intercooler will give a huge increase in power. The cooler denser air will allow more timing because detonation factors are lowered. If remembering correct, expect a 10% increase in power If you maintain the same PSI at engine.

On the 65 ELCO, the computer can see the intake air temps. Sitting in traffic, watch the temps climb, drive it and watch them go down.

Intercoolers are cheap for the no name versions.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

So if you could not hold onto the pipe @ 5 psi, I would guestimate the temp was around 190-200+ degrees?

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Feb 2010

Posts: 136

Contributor

|

Contributor

Joined: Feb 2010

Posts: 136 |

Not meaning to hijack, but Boucher what size pipe did you use? I used 2" on my hot side (from engine to turbo) and 2.5 downpipe (turbo to exhaust)

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

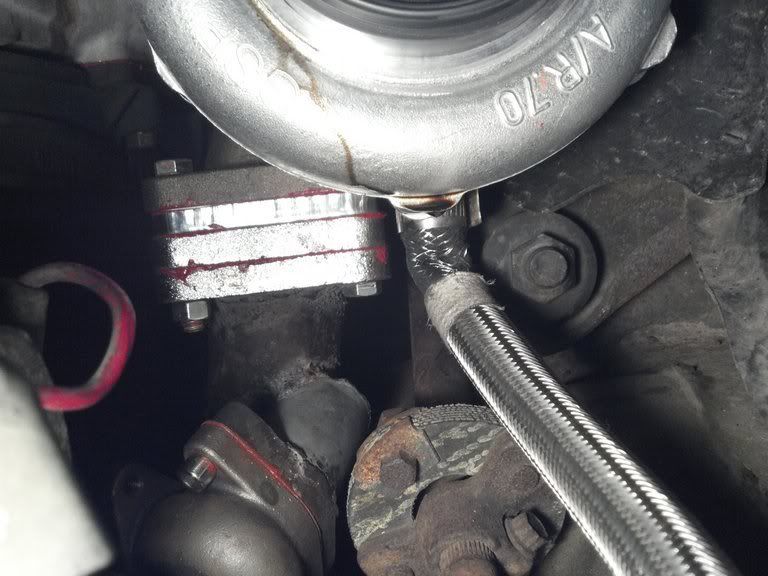

alright guys. Turbo is mounted. All that's left is to do the carb hat, B.O.V., move the fuel line out of the way and do the gauges and exhaust downpipe and out the back. I want to run this car next week at the GS nationals with a bunch of other buicks there. I think it'll be fun being the only turbo six there (probably the only six there at all lol). Only problem now is the intake pipe is going to be very short so my question is can I run this without a blow off valve? I'm definately going to TRY to get the BOV on there but if all else fails, can I run it without?  rear view. There are all of those plates on top of the welded flange because I needed to move it up so it wouldn't hit the A-arm and I didn't want/need/know if I could cut the pipe and weld in a patch and have it work properly. So I bought a 2 more flanges and used them as spacers.  The wastegate  hopefully a better picture of how the wastegate is mounted.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Feb 2010

Posts: 136

Contributor

|

Contributor

Joined: Feb 2010

Posts: 136 |

[quote=Boucher]

B.T.W., never heard about how you got your black exhaust smoke during acceleration resolved.

My T5's first gear is totally non-functional, so its 2nd-5th. Taking off is a bit of a drag. I have a spare NWC T5 that I will swap this winter. As well as fixing the front seal on my rear end.

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

Well hopefully I can get a muffler shop to bend me an exhaust this weekend and hopefully they can bend a 1.5" pipe to meet up with my downpipe so that the wastegate will go out the back too.

Why would I need a 3" downpipe if it's a 2.5" turbine outlet?

and never mind, I found a way to pipe it so that I could put the BOV on it.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Snowman, if you want to go decently fast, you need a large downpipe & big pipe to the back of the car. Three/3 inch" pipeing. ( Minimum 3") Do not skimp out here & dont let the muffler shop tell you they cannot run 3" pipe. Guys have run 4" pipes on 68-69-70 Chevelles. Running a free flowing exhaust sytem will make your engine get into boost faster as does a free flowing intake filter, the larger/longer , the better. You need as free flowing exhaust sytem as possible, meaning, you dont go to a muffler shop & have them crush bend the tubing (that restricts flow), you run mandrel bent tubing & a free flowing muffler (straight through design) You want minimum bends & never have 90 degree bends if possible. Companies, make universal up & over the rear end dual exhaust systems. The one up & over the rear end for my Syclone was made for a 70 Chevelle & just bought for one side. Your wastegate plumbing of the pipe to the wastegate looks like a good angle.  I would not recommend you race your car @ the track so soon. I would not recommend you race your car @ the track so soon.

You need to do a lot of tuning first before you should even consider flooring it.

Just my two cents thrown.It's going to blow up.MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Snowman, when you rejoin the downpipe w/the wastegate 1.5" pipeing, be sure to enter the DP @ a shallow angle. Example.  Notice the somewhat smooth mandrel bent tubing transitions. No sharp bends or crush bent tubing. Also, if can rejoin the your wastegate 1.5" tubing further back into your 3" exhaust system, the better. Make sense? You want a minimun 18"-24" downstream of the turbo downpipe flange for your wategate tubing to re-enter your downpipe. Goodluck w/the muffler shop. MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

alright. So I got the car running and I got to say. TURBOS ARE SO MUCH FUN. OMFGSDLFJAG(OHPSOFBHPOASEF. I got a very nice improvment in power. Only problem now is that the compressor shoots oil when I'm at full throttle!? What would cause that? Too much oil to the turbo? Do I need a smaller feed line? Larger feed line? It's a new turbo so I doubt it's the seals went bad? Is it just factory lube working it's way out? This isn't a good way to start off my turbo-ventures

Last edited by snowman4839; 10/14/11 08:57 PM.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

SNOWMAN,

Before you fired up the engine w/the new turbo, do you prelube the oil feed line to the turbo (make sure you had clean oil coming out of the line w/no metal/garbage coming out of the flex hose that feeds the turbo) & did you prelube the turbo its self?

What size drain did you use to return to your oil pan?

You need to post pics of that for sure.

Lets see the pics of you exhaust system & wastegate plumbing.

How is your idle A/F ratio?

How is your A/F ratio @ wide open throttle?

Where is your timing set at?

What fuel are you using, what octane?

What carb squirter size? What color cam for the accelerator squirter?

Are you just winging this thing?

Are you hearing some knocking/detonation?

I thought you are going to save this original engine for later?

Just giving you some crap because you are not sticking to your original plans.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

SNOWMAN,

Before you fired up the engine w/the new turbo, do you prelube the oil feed line to the turbo (make sure you had clean oil coming out of the line w/no metal/garbage coming out of the flex hose that feeds the turbo) & did you prelube the turbo its self?

What size drain did you use to return to your oil pan?

You need to post pics of that for sure.

Lets see the pics of you exhaust system & wastgate plumbing.

How is your idle A/F ratio?

How is your A/F ratio @ wide open throttle?

Where is your timing set at?

What fuel are you using, what octane?

What carb squirter size? What color cam for the accelerator squirter?

Are you just winging this thing?

Are you hearing some knocking/detonation?

I thought you are going to save this original engine for later?

Just giving you some crap because you are not sticking to your original plans.

MBHD

I ran oil through the line back into the valve cover without the turbo attached. so yes I did. I put a good amount of oil in the turbo while it wasn't on the car just to keep it oiled. the return is a 10AN and the oil feed is a 1/8NPT. Here it is http://www.ebay.com/itm/160647617803?ssP...ht_3659wt_1396.I don't have the A/F set up yet because I need to go the exhaust shop so I can mount in on the downpipe. Timing is at 6 degrees advanced. I had 87 in it but I added 2/3 of a quart of octane booster to it which (according to the can) raised it to about 95. squirter is a 27 I think. Not sure of the cam color ATM. I'm not "winging it". I'm just eager to get the turbo in and I could've told you guys I was going to run a low boost setup on my engine for now and build the other engine and then crank the boost up on the other one. No detonation from what I hear. I really could've sworn I told you guys I was running the low boost setup so I didn't mean to deviate... BUT WHAT WOULD CAUSE THE OIL LEAK?

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Need to post pics of your oil return line installed, not just a link to the kit you bought.

MBHD You are going to need to add more vents to your valve cover, did you do that yet? How much boost are you seeing, do you have a boost gauge to read? The store bought octane booster does not add that much octane. If it says it adds 5 points, that means .5 points.Torrco accelerator stuff really works great to supress detonation. Xylene, is approx 117 octane & can be bought @ paint stores Home depot etc. Toluene 114 or so. If you want to try it. It is not good to breath or to get on your skin etc, be careful when handleing it if interested here is how to mix it. http://www.gnttype.org/techarea/misc/octanebooster.htmlMBHD

12 port SDS EFI

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

Snow,

Show a pic of the drain line and where you routed it.

Can you hear the turbo really spooling up? Like at a super high RPM (turbo) not your engine.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

Hank,

Sounds like you are in a panic, chill out, he's having fun.

Snow,

You better get a handle on a few things like air/ fuel ratios and boost or you will end up with a busted engine.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Nope, not in a panic, just get tired of the kid not listening, so when his engine blows up I dont want to hear, well MBHD told him it would be OK for him to boost his cast piston engine when most everbody else here told him not to. Snowman, did you hook up your boost ref line to your fuel pump? Enjoy! MBHD Hank,

Sounds like you are in a panic, chill out, he's having fun.

Snow,

You better get a handle on a few things like air/ fuel ratios and boost or you will end up with a busted engine.

12 port SDS EFI

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

Even if that happened, still not your fault.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Just something to add while your injesting oil.

When your engine is injesting oil like it is, this will effectivly lower your octane rating & could cause your engine to detonate.

So Snowman, how is the power?

Does it feel faster than the 4bbl set-up you ran?

Don't get me wrong. I am excited for you Snowman.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 631

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 631 |

I think I found the culprit in the pictures. Probably the slight kink coming out of the turbo. Would that cause the oil to back up and then sqeeze itself out of the seals into the compressor housing?    Ok. Where have I not listened? The way I figure it now. I'm running it very rich and with hardly any timing. Aren't those the only 2 things that would cause detonation? That's why I figure it's safe to mess around with the stuff for now. I'm sorry that I'm excited that I get to use the parts that have been sitting in my room for 6 months and what we've been talking about doing for like a year. Yes, I'm a teenager, I might get a little overzealous sometimes. I'm a big boy. I won't go blaming it on you if anything goes wrong. I have the final say in what happens so who else is there to blame? Yes I hear the turbo spooling pretty well. Why? Why would I need more valve cover vents? It has a 2 decent sized ones on the stock cover? I've looked into Xylene and Toulene but IIRC, it erodes your tank and lines quickly and I also could never find it anywhere in large quantities for better deals. no I didn't hook up the boost line to the fuel pump yet. I wanted to see if it would be necessary since the stock fuel pump probably puts out just a hair more pressure than the low boost I'm running. But if I do notice dying after full throttle then I can conclude I'm draining my fuel bowl and that would necessitate fixing the fuel pump. But if it works like it is, why mess with it? I know I'll need to fix it when I put the stuff on the other engine. EDIT to respond to MBHD: even if it is effectively lowering my octane, I'm still running rich and without much timing. It feels like my 4 barrel setup up through 2000rpm, then it substantially gets a lot more power and then levels off at about 2800rpm. I easily spun the tires all the way through first gear whereas with my fourbarrel, it would catch about halfway through because it couldn't power it through.

Last edited by snowman4839; 10/14/11 10:31 PM.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

0 members (),

334

guests, and

20

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|