|

|

Joined: Sep 2001

Posts: 510

Major Contributor

|

Major Contributor

Joined: Sep 2001

Posts: 510 |

It's a rare item, and it appears to be mostly complete, with several accessories, but i don't think it will sell at that price.

It might find a buyer at one-third of that price, but not much more.

God's Peace to you.

d

Inliner #1450

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

For those curious: this does not include the cam, because any original or replacement cam could be used. This is because the stock valve sequence (E-I-I-E-E-I-I-E-E-I-I-E) was used, although with individual cross-flow ports.

Some other manufacturers, such as Howard, changed the valve sequence to I-E-E-I-I-E-E-I-I-E, which requires a new cam.

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

This would be worth more as racing parts if for the GMC engine, since the 235 is far too small to be competitive in XXO.

|

|

|

|

|

Joined: Feb 2009

Posts: 127

Contributor

|

Contributor

Joined: Feb 2009

Posts: 127 |

|

|

|

|

|

Joined: Apr 2007

Posts: 92

Active BB Member

|

Active BB Member

Joined: Apr 2007

Posts: 92 |

Thatís for sure. Hoyt that section view is priceless, Mark thanks for putting up the picís. and Tom thanks for bringing it up in the first place. Is there any reason it would not be possible to convert a 261 core to accept a 15 bolt head and/or how much different is the positioning? I think I would go as high as half the asking price at my weakest moment.

1952 Chev 1300 Cdn. Ĺ ton

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

The 2 obviously extra bolts are between the rocker stands. I've read that it's possible, but you'd have to super-impose the head gaskets to see how far off, and there may be length differences in the bolt perch as well.

|

|

|

|

|

Joined: Dec 2004

Posts: 226 Likes: 1

Contributor

|

Contributor

Joined: Dec 2004

Posts: 226 Likes: 1 |

Which would be more practical-converting a 15 bolt head to 18 or a 18 bolt block to 15? Not having the engineering knowledge of many involved in the extreem performance world I thought this might be a good question. Wouldn't it be better to have 18 head bolts? I OL REDNECK

DARRELL KRAFT I.I.#113

|

|

|

|

|

Joined: Apr 2005

Posts: 364

Contributor

|

Contributor

Joined: Apr 2005

Posts: 364 |

I've heard that Hank Lawshe had a modified 15-bolt head on a 261 in his coupe that set a Bonneville record a few years ago. Does our new historian have any more information in the archives? Jerry Weigt or Gary Cope would probably know what it takes to mix the heads and blocks.

Hoyt, Inliner #922

|

|

|

|

|

Joined: Nov 2005

Posts: 504

Major Contributor

|

OP

Major Contributor

Joined: Nov 2005

Posts: 504 |

And is the bottom line still just 40 HP?

Tom

I.I. #1475

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

I just made an overlay of both decks, and it appears that:

1. the 8 bolts in the row on the left (port) side are very close, if not the same

2. you have to add 2 bolts between rocker stands 1 & 2 and 5 & 6

3. the existing 15-bolt stand bolt between 3 & 4 is off quite a bit

4. there's a bolt missing midway along the pushrod side

5. there may be other errors on the pushrod side, but the other 6 bolts are pretty close

If you have P/Shop, e-mail me and I'll send you a .psd, you can slide the opacity control for the top layer to watch the bolt holes change.

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

Assuming that an early head + late block is the goal?

I would guess that the minimum is:

1. drill and tap the block for the 15-bolt center stand position

2. bore the head for the 2 extra stand bolts if it looks safe (enough material, no water underneath), otherwise leave them out and plug them in the block

3. plug the original 18-bolt center stand hole

What I don't know is where the water transfers. The early heads have 8 copper water nozzles pressed into the gasket surface to cool the exhaust valve seats, and I can't tell if they line up with the late block.

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

|

|

|

|

|

Joined: Apr 2005

Posts: 364

Contributor

|

Contributor

Joined: Apr 2005

Posts: 364 |

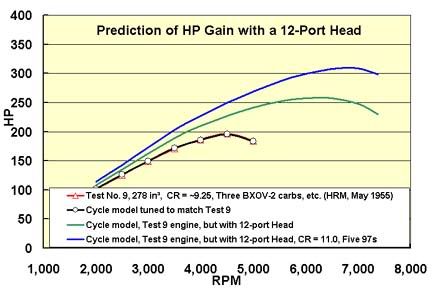

For what it's worth, I ran the flow characteristics (as best I know them) of the 12-port head through an engine simulator that had been tuned to match the results of the dyno tests by Frank McGurk in the May 1955 HRM. The results indicate that, if one has the nerve to take a stovebolt crankshaft and valve train to 6500-7000 rpm, the peak HP gain could be 60 to 100 HP. [url=  ][/url]

Hoyt, Inliner #922

|

|

|

|

|

Joined: Oct 2000

Posts: 368

Contributor

|

Contributor

Joined: Oct 2000

Posts: 368 |

I have seen a few 15 bolt 12 ports on 18 bolt blocks, including those by Jerry Weigt, Hank Lawshe, and Keith Young. As I remember (it was quite a while ago) most head bolts line up, and the ones that don't (1 or 3?)in the block are plugged and redrilled to match. Only 15 head bolts are used.

Tim Tenold

I.I.#498

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

As some scary Slant 6 motors have shown, 4 mains isn't automatically a low-speed engine.

Based on a GMC rod, light piston, and SFI-quality damper, 7,000 RPM is about 113,000 f/s/s, a very conservative figure for a race engine (lower stress than a SBC 350 with 5.7" rod at 7,377 due to lower piston weight).

The mean piston velocity is 4,594 - not good, but possible with a quality forging.

The RPM will require a steel cam for the spring pressure, and probably a fabricated rocker arm or welding and doubling to stiffen the original (which may turn out to be Buick L8 or GMC?).

|

|

|

|

|

Joined: Nov 2005

Posts: 504

Major Contributor

|

OP

Major Contributor

Joined: Nov 2005

Posts: 504 |

So, all these years later, are there any 12 port heads for the 235/261 series??

Last edited by 6inarow I.I. #1475; 07/27/14 01:11 PM. Reason: cant spell

Tom

I.I. #1475

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

I am sure if they were available cost would be around $4500-$5000 maybe more.

You are really going to want that cylinder head to pay that price.

Problem is there is even less demand for those engines than the 194-292 engines.

They weigh as much as a BBC & the potential performance gain is limited by the design of the engine.

Maybe I am wrong?

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

Tom, I am in a position where I can/could very easily make one for these engines. The question is simply, who is going to spend $2000-$2500 just for a cylinder head, and then the other support components like intake, exhaust, etc for a Stovebolt anymore. If 10-15 people would step forward and raise their hands then that could get the ball rolling. Start a list and see who else will join in.

Class III CNC Machinist/Programmer

|

|

|

|

0 members (),

125

guests, and

27

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|