|

|

Joined: Jan 2009

Posts: 22

Active BB Member

|

OP

Active BB Member

Joined: Jan 2009

Posts: 22 |

I have a cylinder head off of a Chevy 292 inline six that I would like to mildly port, polish, and port match the intake for my father's '82 C-20. I think I have found the casting number inside of the valve train area. Right below the rocker arm tips towards the rear of the engine there is "GM" in large lettering and right below it is a number that reads 03400104. I don't know if this is the casting number or not. It could also be 83400104 because the first digit isn't so clear. I want to get a set of Crower roller tip rocker arms (CRO-72829-12)and matching push rods. Thanks for any help that you guys/gals can give me :).

Chickenbone

|

|

|

|

|

Joined: Jun 2008

Posts: 154

Contributor

|

Contributor

Joined: Jun 2008

Posts: 154 |

This might help: http://www.inliners.org/tech/heads/headindex.htmHowever, I have a '85 292 and wasn't able to find any info on my casting numbers. So don't get your hopes up. Not sure what good knowing the head casting is on a 292 anyway. They had big combustion chambers and low compression, not really worth much for performance. If you want performance find a 250 or 194 head to boost compression. Your time and money would be better spent working with those. also be aware that if you are using stock type pistons, most aftermarket stock type pistons have deeper dishes than the OE pistons, so you'll most likely be loosing compression anyway. There are way to get around this by using particular kinds of pistons and the guys on here can help you, but it's just another thing to consider during your build. Also it's only a matter of time before somebody mentions lump porting. Unless you plan to race they aren't really necessary. Although they do dramatically improve the performance of the heads.....just very expensive to have installed. (approx $550-600+)

'40 Studebaker project Chevy 292 powered.

'51 Chevy business coupe 216ci inliner

Inliner's #5360

|

|

|

|

|

Joined: Jul 2000

Posts: 4,592 Likes: 20

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,592 Likes: 20 |

trump

The 292 heads are NO different then as 250 head They Both had the same CCs depending on the casting.

chickenbone I would recheck your numbers. Also Look to see if it says Mexican on it anywhere.

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Jan 2009

Posts: 22

Active BB Member

|

OP

Active BB Member

Joined: Jan 2009

Posts: 22 |

Yeah, it says Mexico on the left hand side (towards the front of the engine). Would this make a difference?

Chickenbone

|

|

|

|

|

Joined: Jul 2000

Posts: 4,592 Likes: 20

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,592 Likes: 20 |

Not really but that is why you can't find a casting Number to match up with any CCs. Not something I have seen listing/records of.

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Jan 2009

Posts: 22

Active BB Member

|

OP

Active BB Member

Joined: Jan 2009

Posts: 22 |

I was just trying to get as much info on the head as possible before I bring the head to the machine shop. Also, I wasn't sure which parts will fit what head(s) and I definitely wanted to know that before ordering.

The '82 C-20 was my father's welding rig for the last 12 years. Then he got an '00 F-250 Superduty for the welding and kept the Chevy for the cruising. I'm probably going to keep the stock cam in there because it seems to have a lot of low end grunt in case he needs the truck for hauling the backup equipment.

Chickenbone

|

|

|

|

|

Joined: Jan 2009

Posts: 22

Active BB Member

|

OP

Active BB Member

Joined: Jan 2009

Posts: 22 |

I just got around to cleaning off the cylinder head and the valve cover. I will have to have another go at the cyliner head because it's still a little greasy and I didn't get the valve train clean enough. From what it looks like, the other 292 was pushing oil. The head gasket was in good condition. Perhaps the valve seals were gone. All of the combustion chambers were black. Number 3, 4, and 6 combustion chambers were greasy. They probably blew the engine and junked the truck afterwards. After I got the head home, my father and I pulled the intake and exhaust manifolds apart. We mocked up one of the headers (two pieces) and to our surprise, the flanges on the headers and intake were the same thickness. So at least making spacers to compensate for any difference won't be a problem. We also took the dowel pins (actually they look like studs that were cut off in the middle) out of each end of the head because we think that we'll need to bolt the headers in those locations because the the steel headers will probably move a lot more than the cast iron exhaust manifolds and will need more support. We're also thinking about using the work bench as the cylinder head stand. We'll bolt the head down to the work bench and then hang the intake, headers, alternator bracket, and the power steering pump bracket to the cylinder head to see how everything is going to fit. For now, the plan is to set up the headers on his running 292 and run them with the stock engine. Then we will send the other cylinder head down to the machine shop if the header installation presents no problems. It seems like it's twice the work, but in the end, we believe it will be easier to track down problems if they should occur.

Chickenbone

|

|

|

|

|

Joined: Jan 2009

Posts: 22

Active BB Member

|

OP

Active BB Member

Joined: Jan 2009

Posts: 22 |

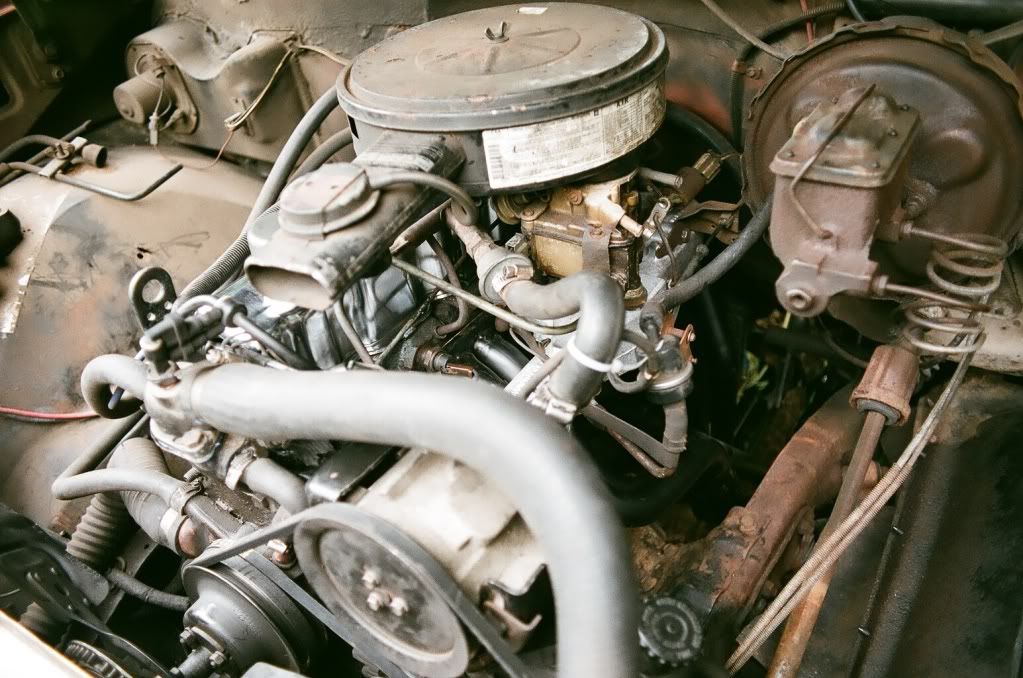

Here are some pics of the 292 cylinder head, intake/exhaust manifolds, radiator, and air intake tube from the 292 that we tore down a few weeks ago.   Chickenbone

|

|

|

|

|

Joined: Jan 2009

Posts: 22

Active BB Member

|

OP

Active BB Member

Joined: Jan 2009

Posts: 22 |

|

|

|

|

|

Joined: Jan 2009

Posts: 22

Active BB Member

|

OP

Active BB Member

Joined: Jan 2009

Posts: 22 |

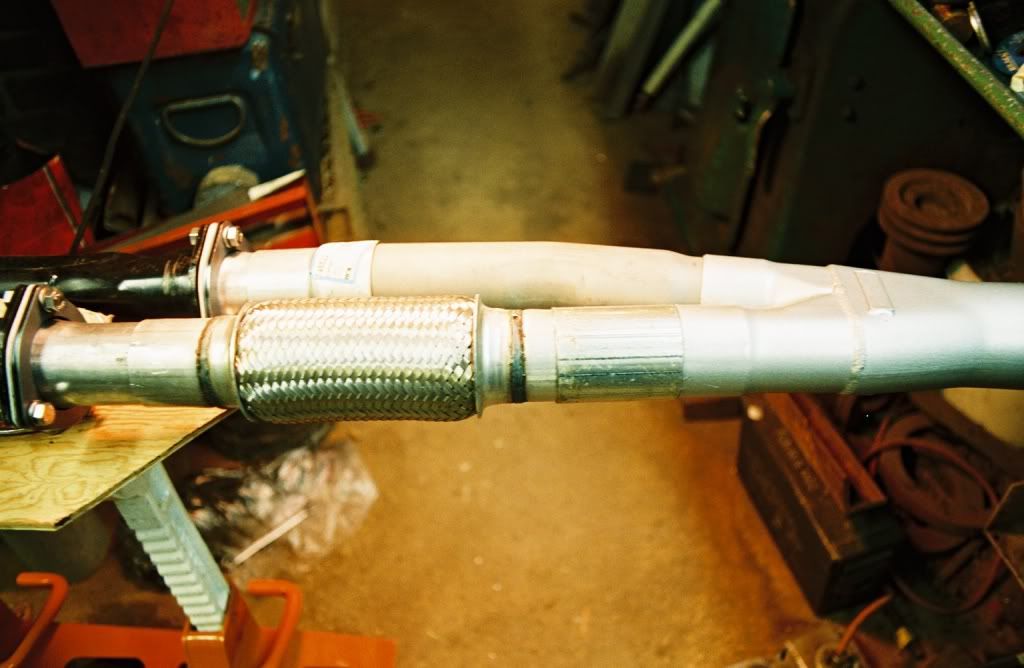

I have been working on the house as of late and just got back to working on the 292 again. We installed the new radiator off of the other truck. We also installed the complete air cleaner assembly as well. The 292 seemed to like that. We also took all of the remaining tools, welder, and tanks off of the truck. With all of that unsprung weight, the truck is subsequently snappy. I scored a stock Chevy valve cover off of a '67 Camaro with a 250. I also got various collectors and a Flowmaster Y-collector for the exhaust. We spent an hour mocking up what we'll be temporarily running on the C-20. Here are some pics of the progress so far. Once we make some final cuts and ginding, I'll take the headers out to be sandblasted so I can put some hi-temp coating on them. Not pictured is the 2.5" muff that I'm waiting for.    Chickenbone

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

hey chickenbone,

great to hear about the progress for your truck. could you see if there is a way you can post thumb nail size pics in the future? for some of us the net is a very slow function. not quite as slow as dial up though. when you put up full size pics, i have to wait for one heck of a long time. makes me not want to read your posts. but i will anyway.

now keep on wrenching. tom

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Jun 2007

Posts: 1,411

1000 Post Club

|

1000 Post Club

Joined: Jun 2007

Posts: 1,411 |

Looks very nice.

Just a question, not nit picking, are you collecting the two into one that close to the header collectors for clearance?

I'm not the worlds' expert or anything, but I was wondering if a somewhat longer 'secondary' length might benefit bottom end and midrange some?

Just asking, not telling.

My, what a steep learning curve. Erik II#5155

|

|

|

|

|

Joined: Jan 2009

Posts: 22

Active BB Member

|

OP

Active BB Member

Joined: Jan 2009

Posts: 22 |

I used the Y-collector that close to the headers because it was the only way I could get it to fit right. If I had it my way, the header collectors would be longer, but most catalog headers have collectors that are too short. I wanted to install an H-pipe with a dual 2.25 exhaust, but it would take more work for my father and I to get that to work. So it will be a decent sized single for now. In any event, it will be much better than what he has on the 292 now.

Chickenbone

|

|

|

|

|

Joined: Feb 2003

Posts: 163

Contributor

|

Contributor

Joined: Feb 2003

Posts: 163 |

While you have the headers bolted to the head, drop a straight edge straight down off the head and tell me how far out away from the head the headers are. I don't have much room in my '37 from the block to the frame rail, and I curious how wide those headers get down by the oil pan area.

Joe

|

|

|

|

|

Joined: Jan 2009

Posts: 22

Active BB Member

|

OP

Active BB Member

Joined: Jan 2009

Posts: 22 |

Again I apologize for the late reply. The furthest header collector measures approximately 10" away from the cylinder head. That's for these particular truck headers. I don't know if they make headers for Camaros and Novas that also received these engines. They may be tighter.

Chickenbone

|

|

|

|

|

Joined: Jan 2009

Posts: 22

Active BB Member

|

OP

Active BB Member

Joined: Jan 2009

Posts: 22 |

Jeez, I haven't moved much since my last post. I got the headers grinded out a bit and the fitment is much better. They don't touch the intake anymore as well. I'm just waiting for the weather to get a little warmer to do the install. In the meantime, I got a MSD 6AL and 8mm plug wires to install. I might spring for a new MSD dizzy as well. The stock ignition module died last month and my father had a friend install one off of the 250 dizzy he had lying around. It seems to work. I'm currently trying to convince him to let me get an Offy intake and a Holley 390cfm carb. I'm not crazy about the stock 1 bbl Rochester that's on there now.

Chickenbone

|

|

|

|

|

Joined: Jan 2009

Posts: 22

Active BB Member

|

OP

Active BB Member

Joined: Jan 2009

Posts: 22 |

I finally got the C-20 freed up to do the exhaust, which consists of Pacesetter LT headers, flex joint, a bent up piece of 2.5" pipe, the Flowmaster Y collector, some 3" pipe, and a Summit Racing muffler. I had to get a custom bent piece of piping because the headers hang a little lower and to the left of the crossmember. The 292 seems to be a well balanced engine. It doesn't pop when you let off of the throttle, even with it straight piped. It also seems to run smoother and gained a little low-end torque. I can pull off in second without much throttle. My father hasn't driven the truck yet, so I'm waiting for his input. I might just get some 2.5" glasspacks behind the Summit muff. It's deathly quiet at idle, but it's a different story when you get on it a little. I also had the intake hot tanked. When it came back from the speed shop, I coated it with Eastwood silver manifold coating. Here's some pics of the engine before and after with a shot of the mod'd smog pump bracket. Oh yeah, I apaologize for the larger pics. I tried using the site's uploader and my computer nearly freezes; it's easier to use a host site. Next tech thread (if that's what this is) will have a bit more patience and smaller pics.       Chickenbone

|

|

|

|

0 members (),

414

guests, and

28

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|